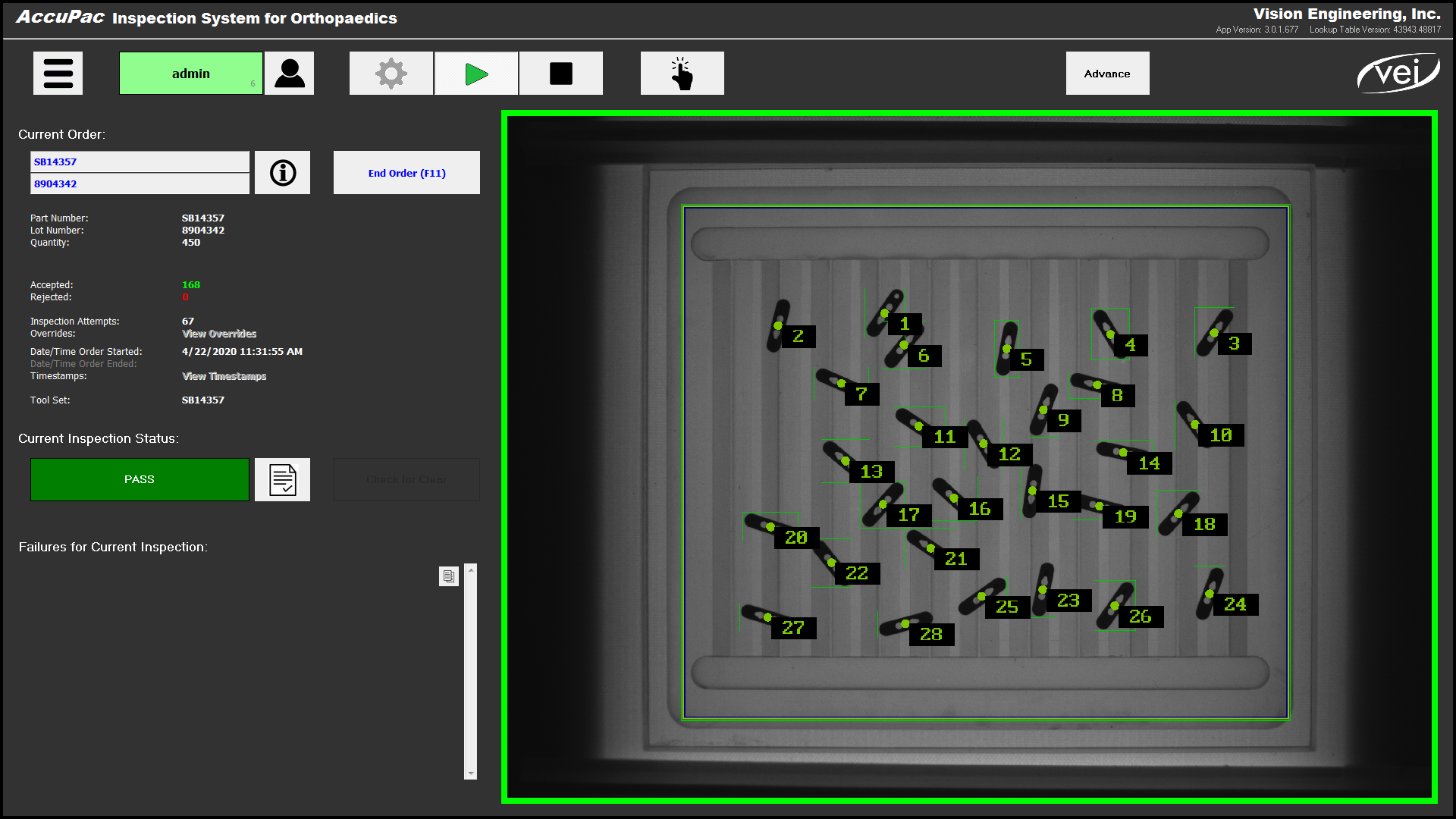

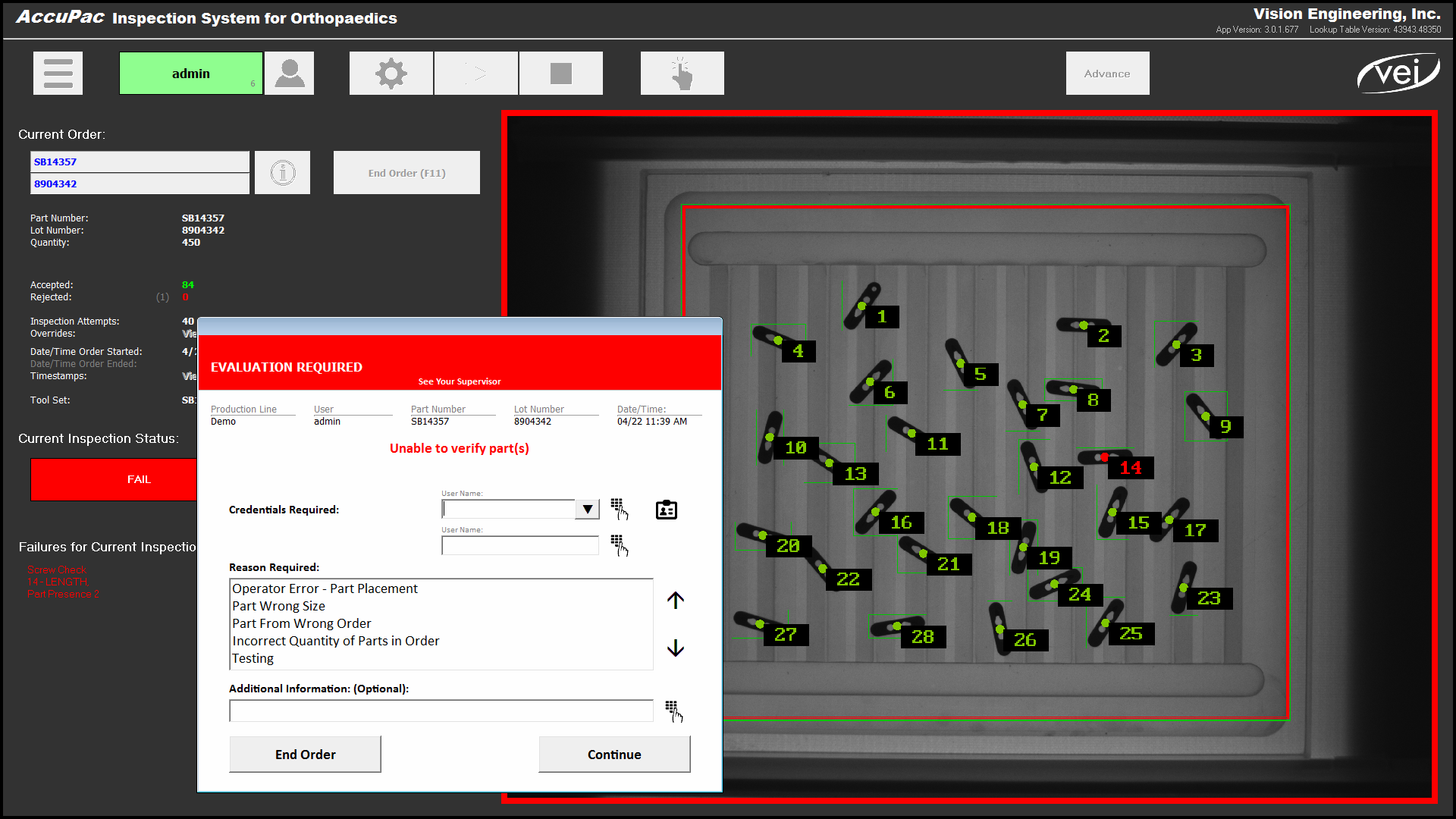

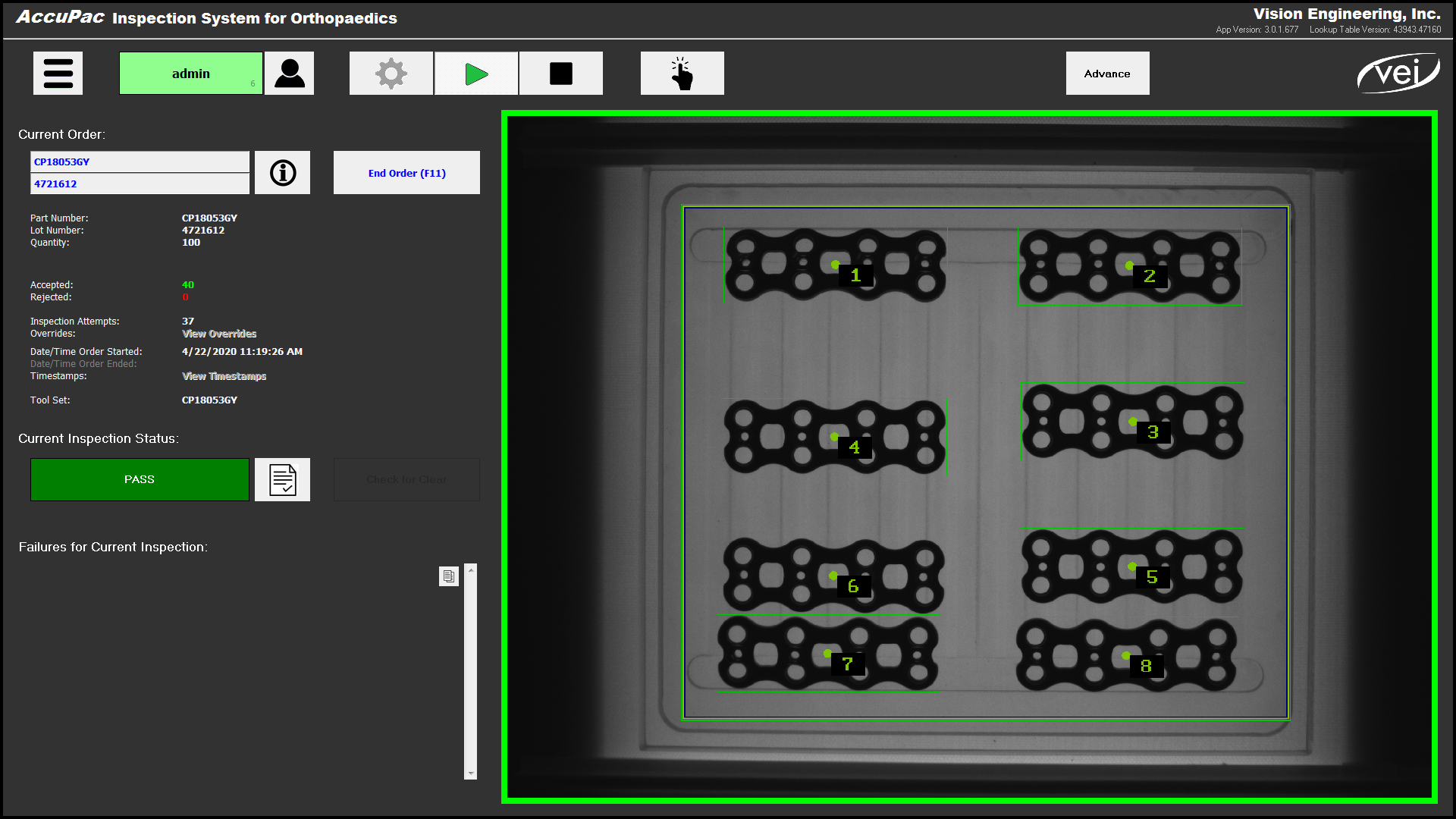

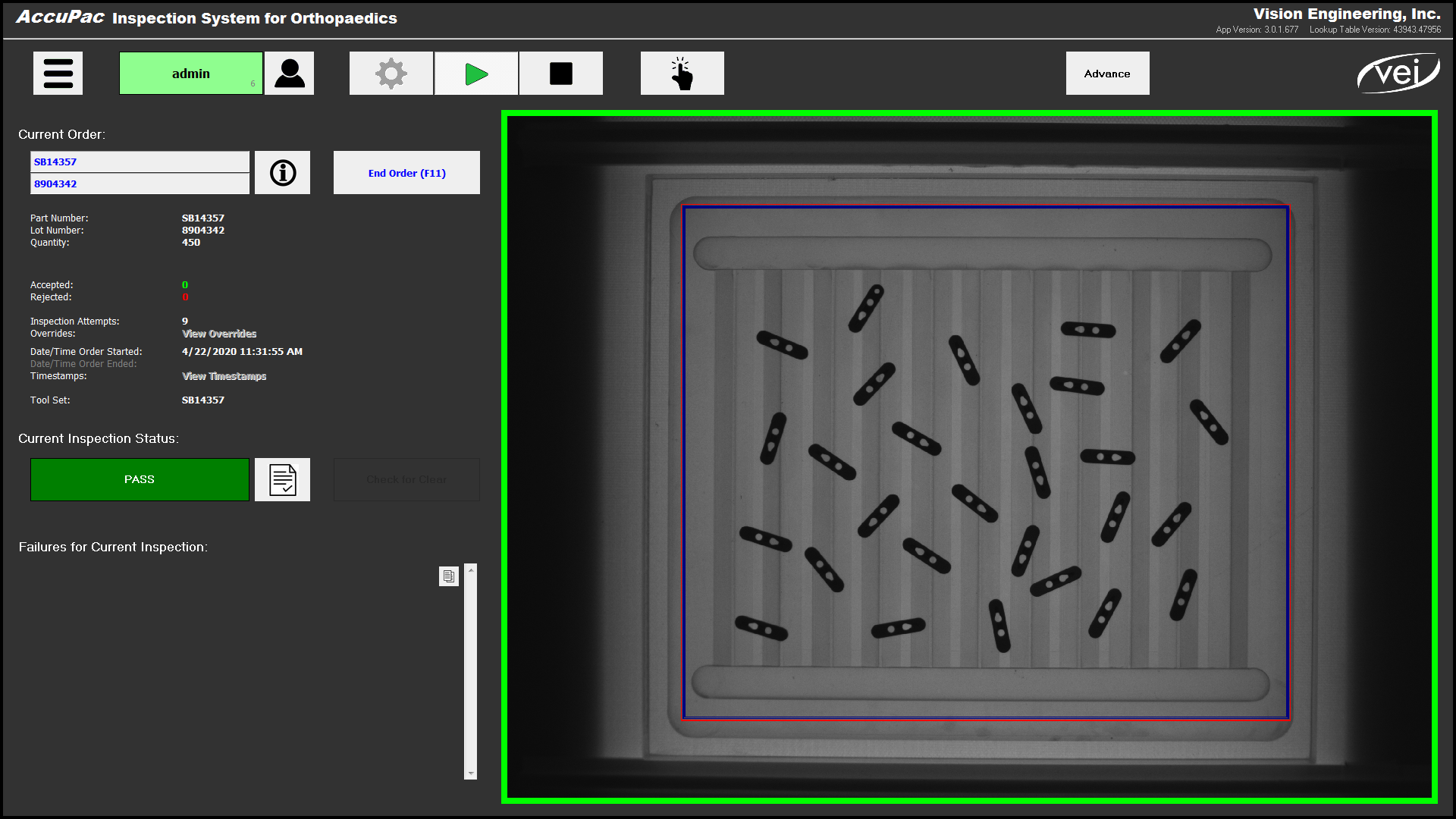

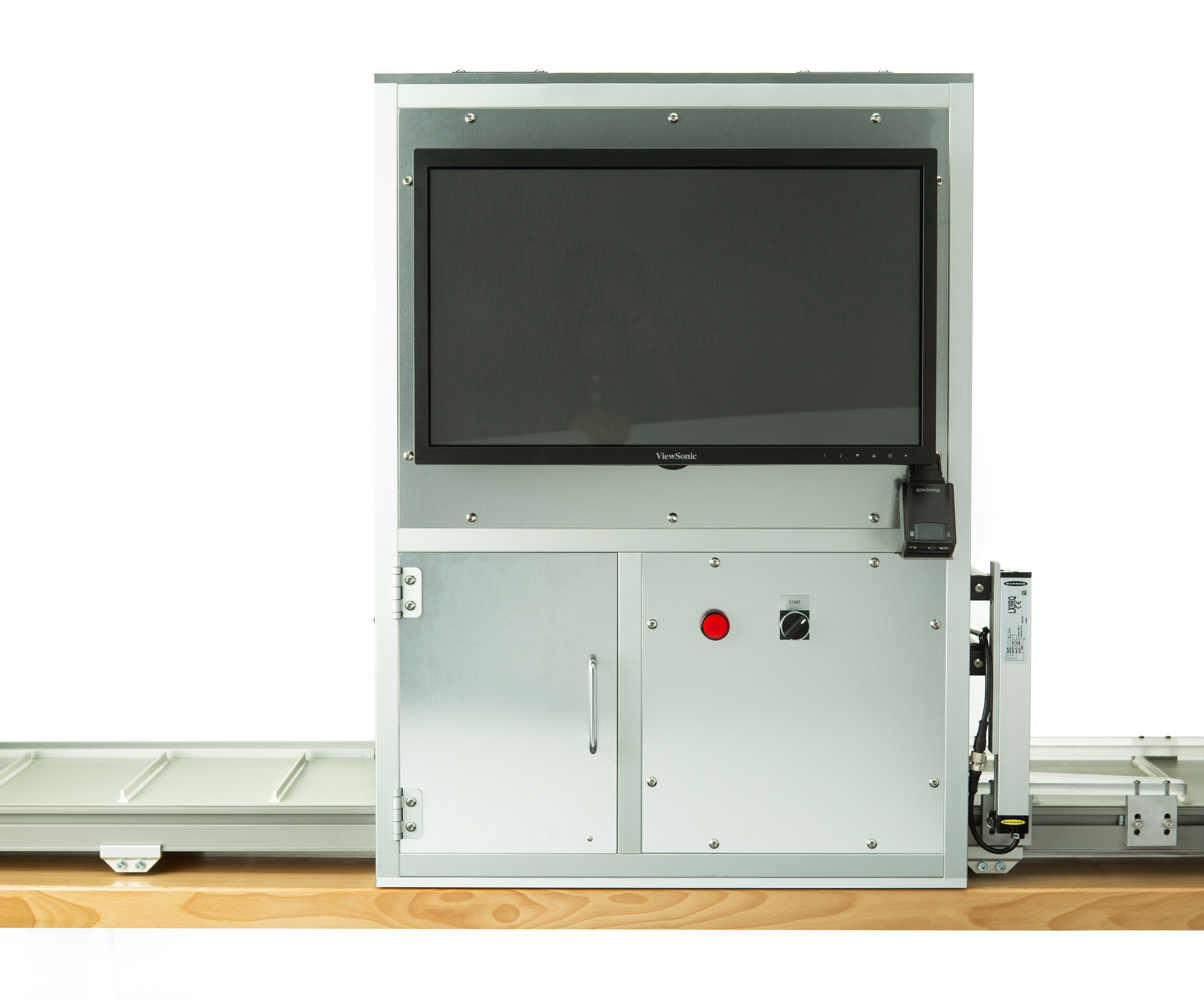

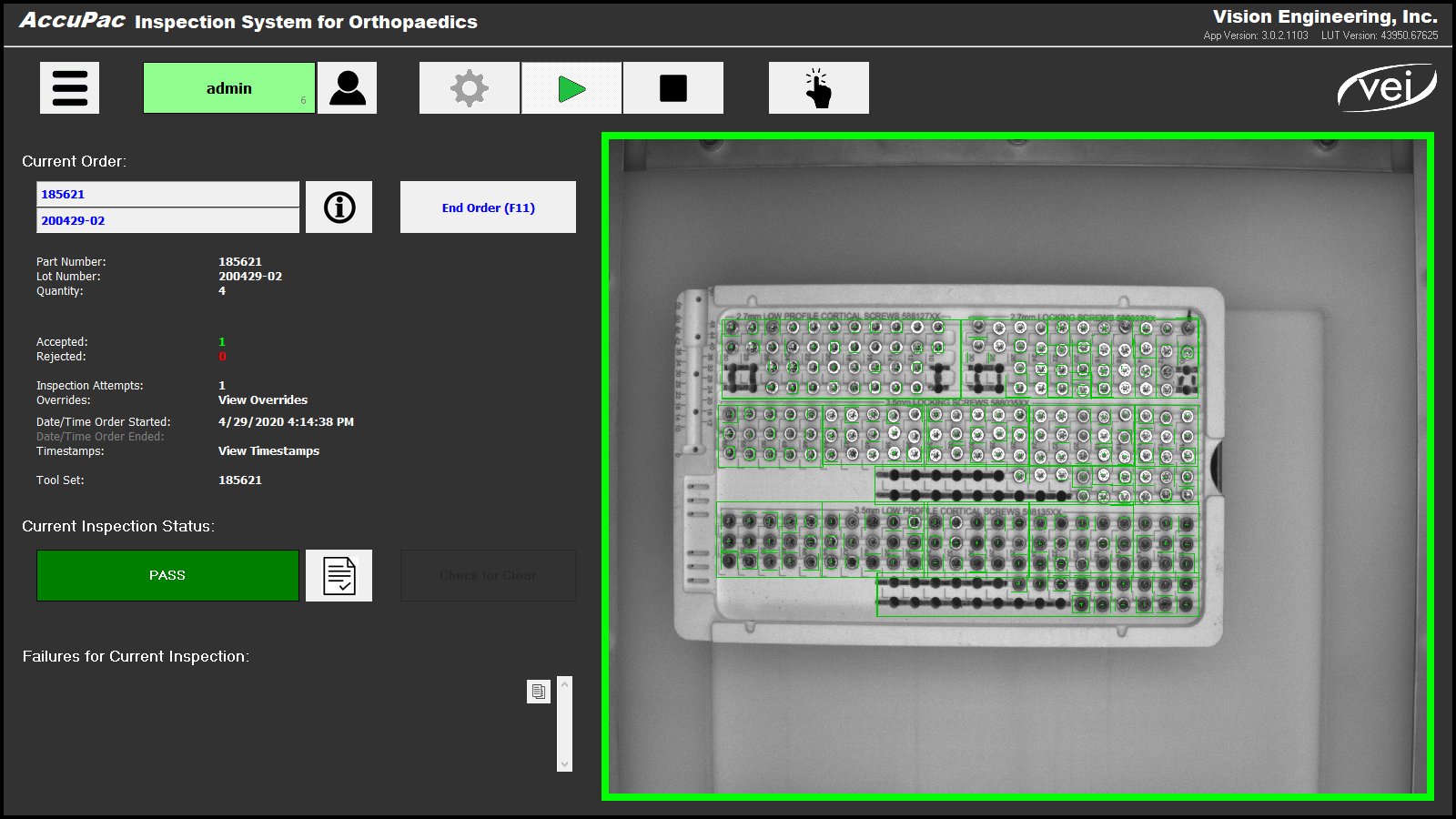

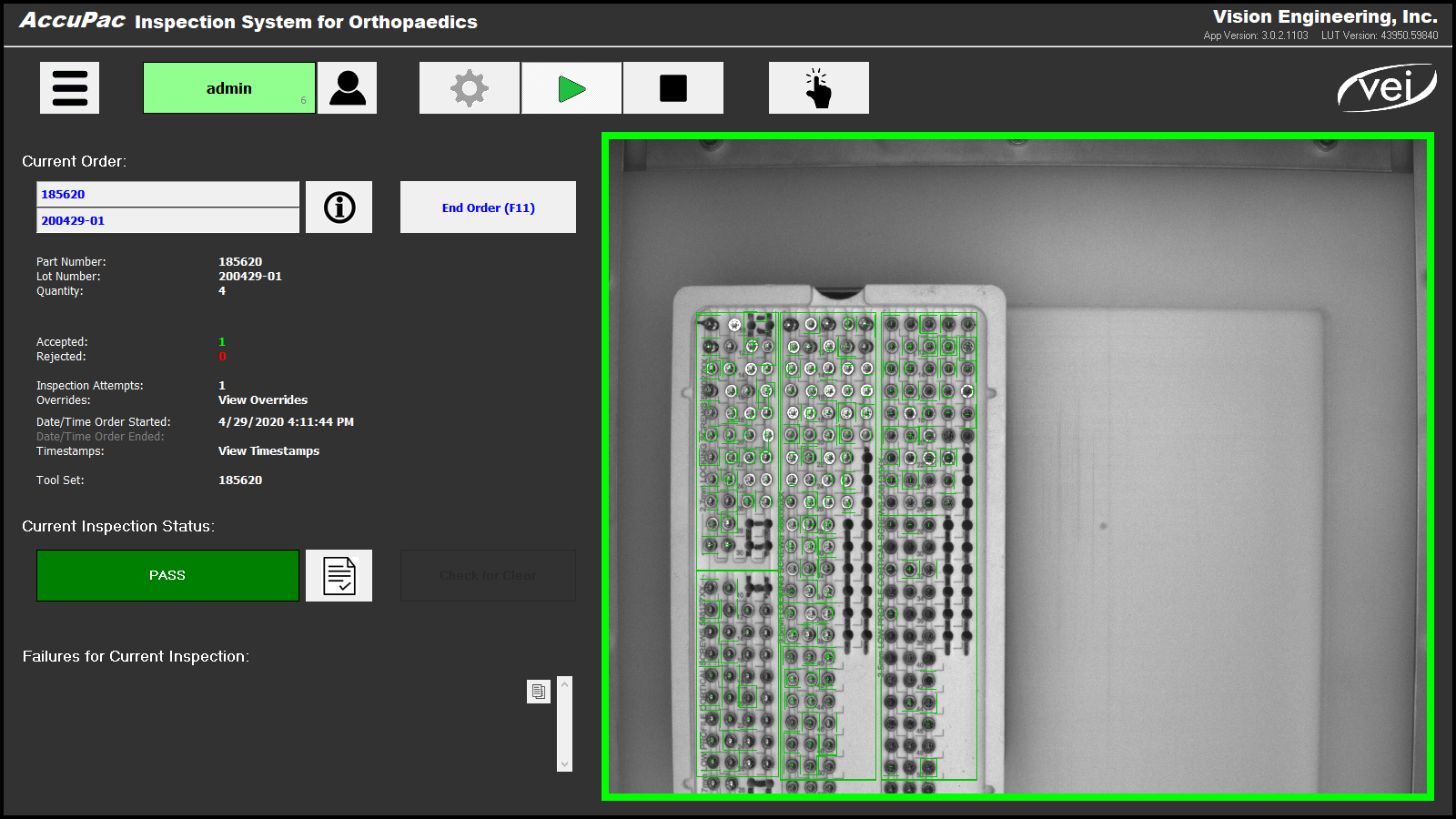

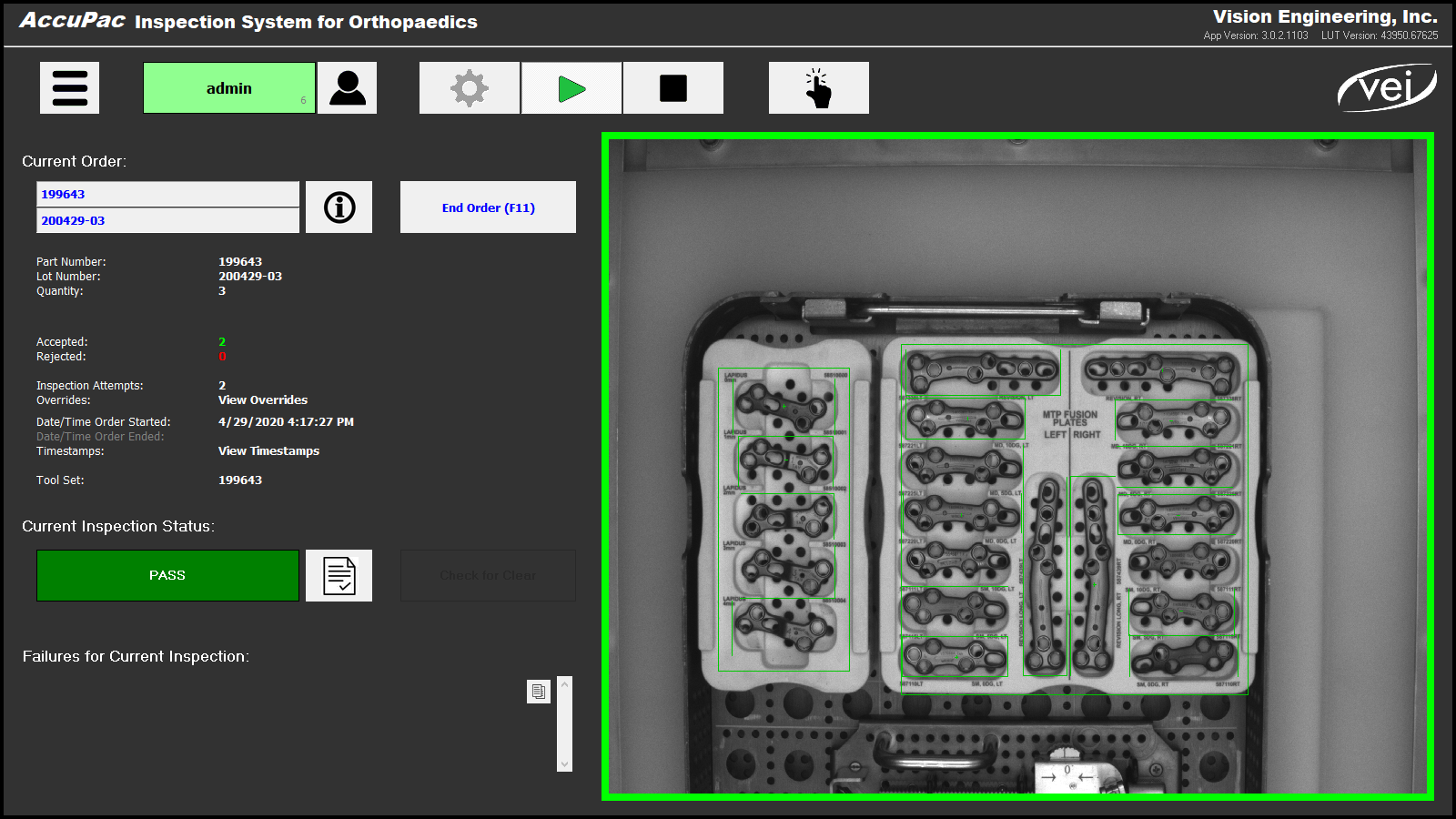

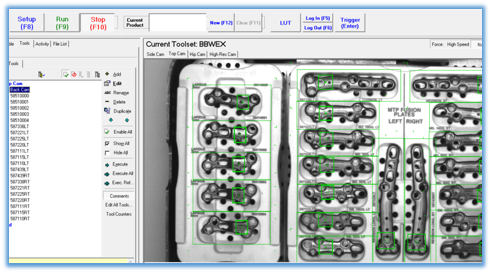

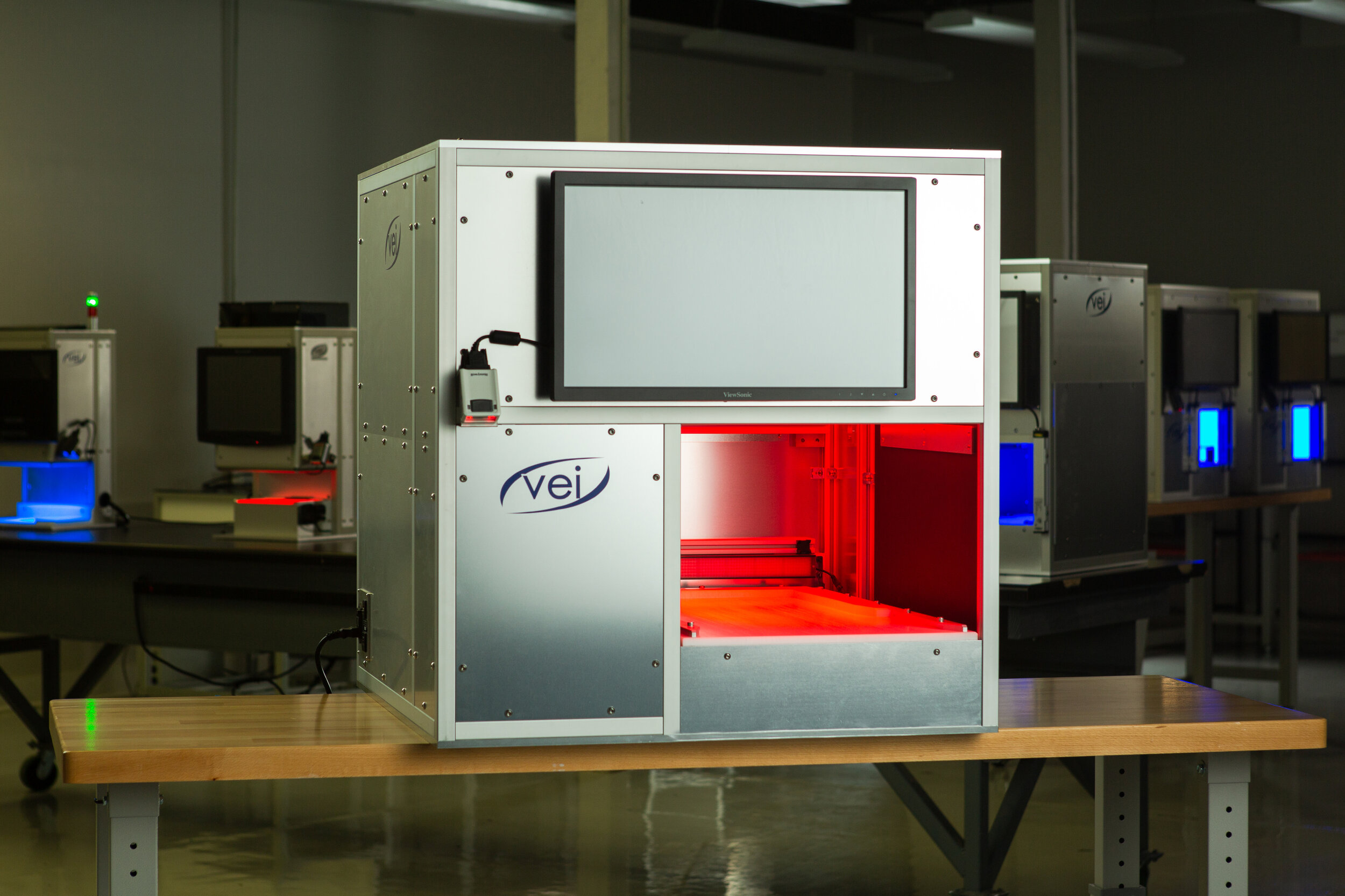

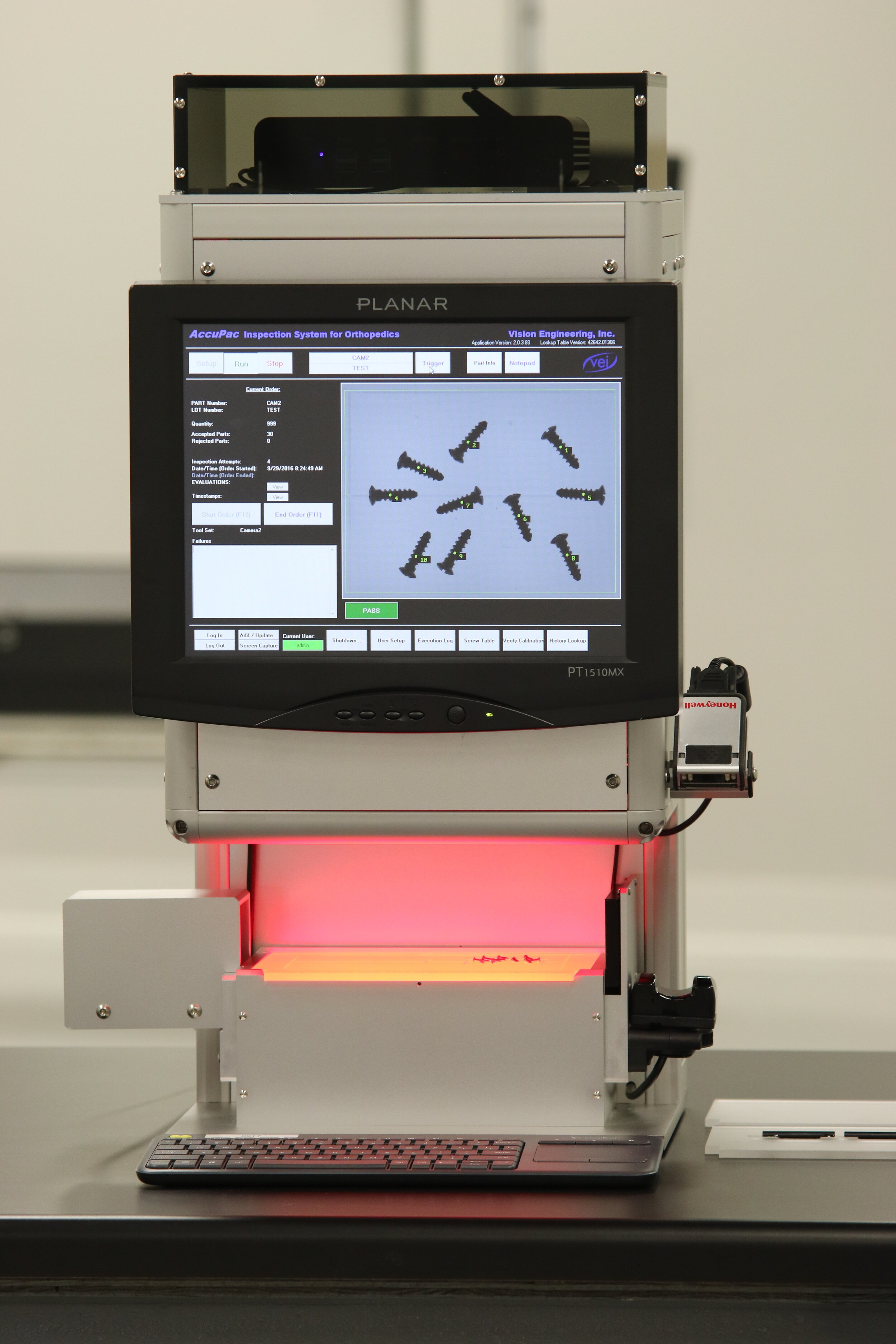

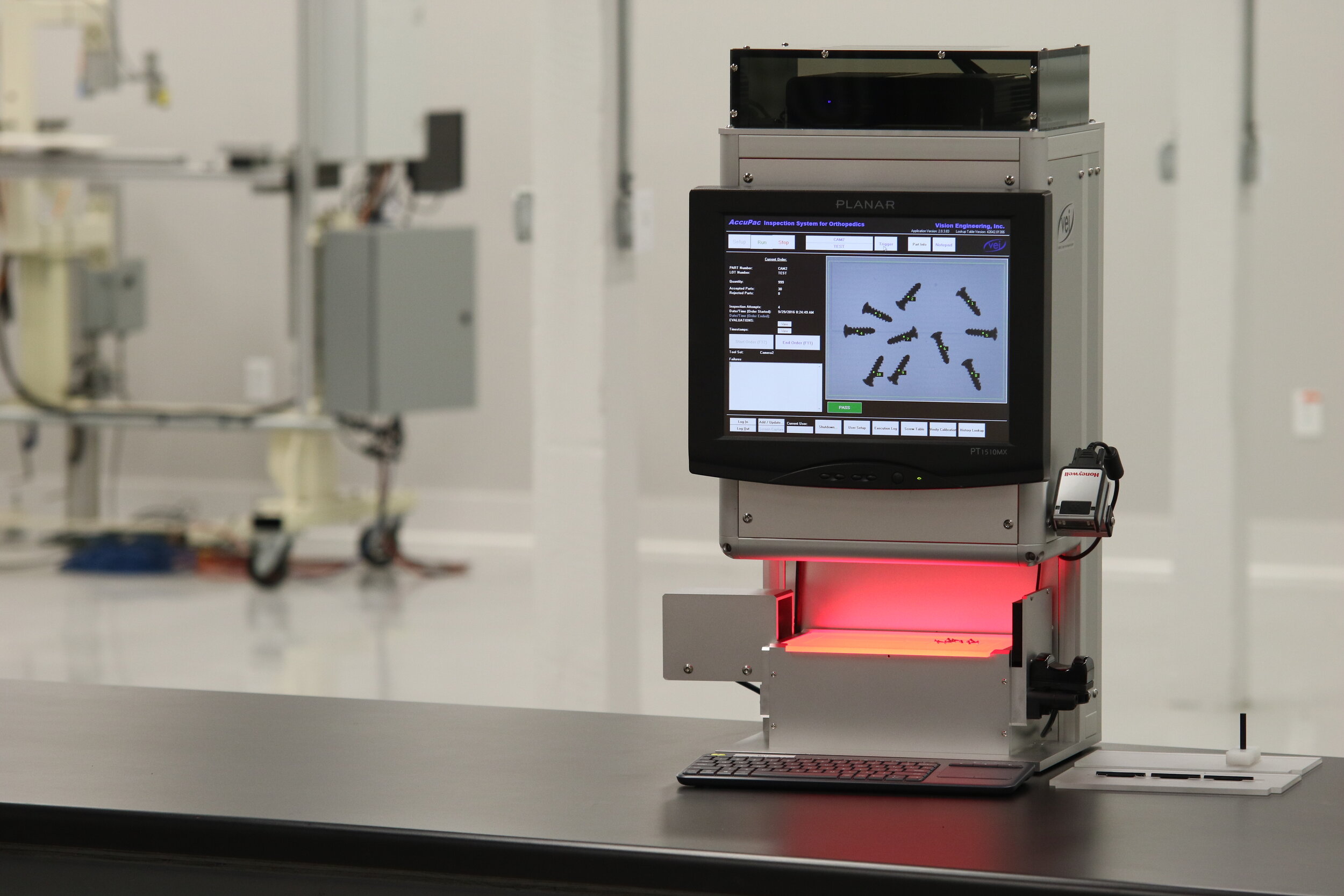

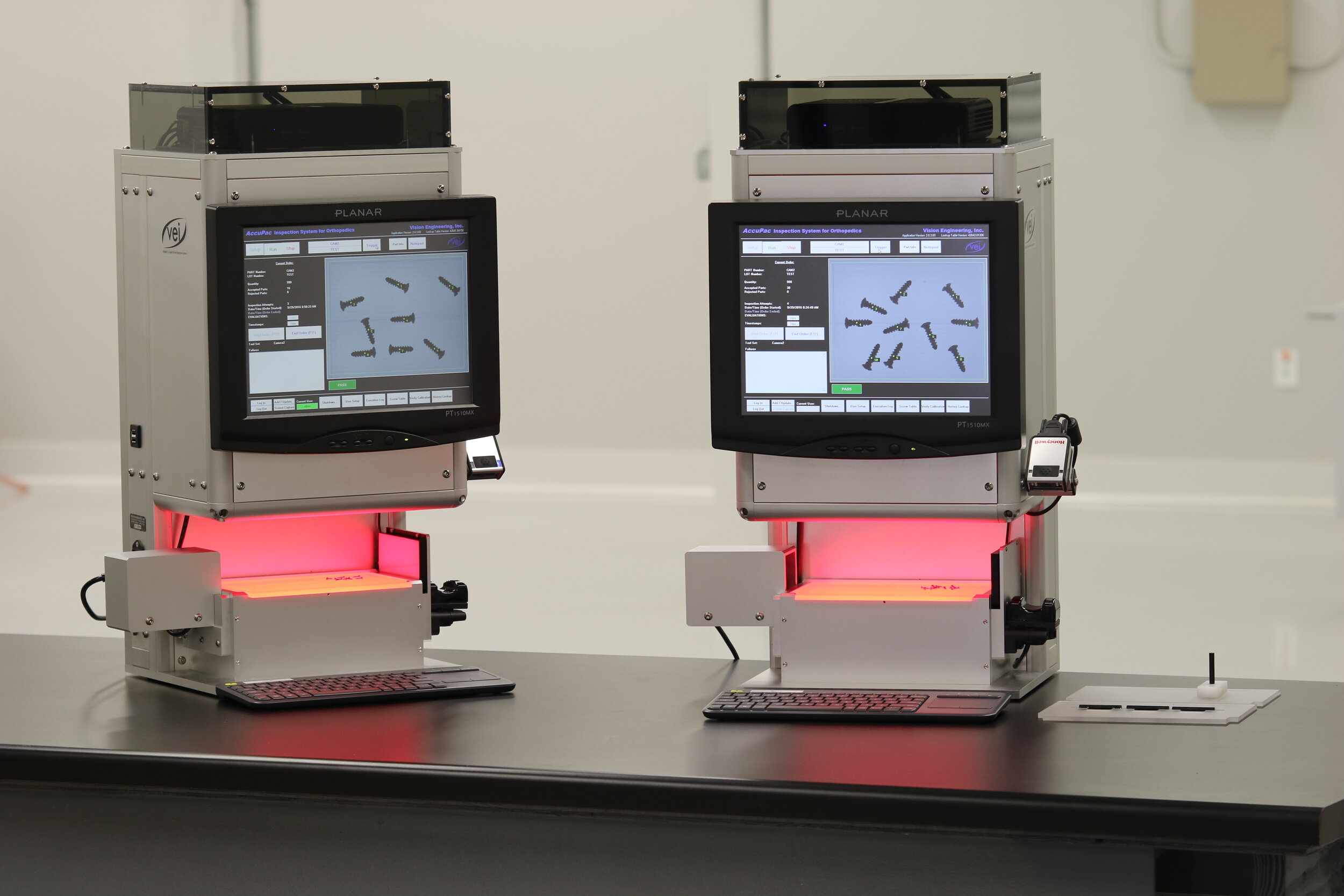

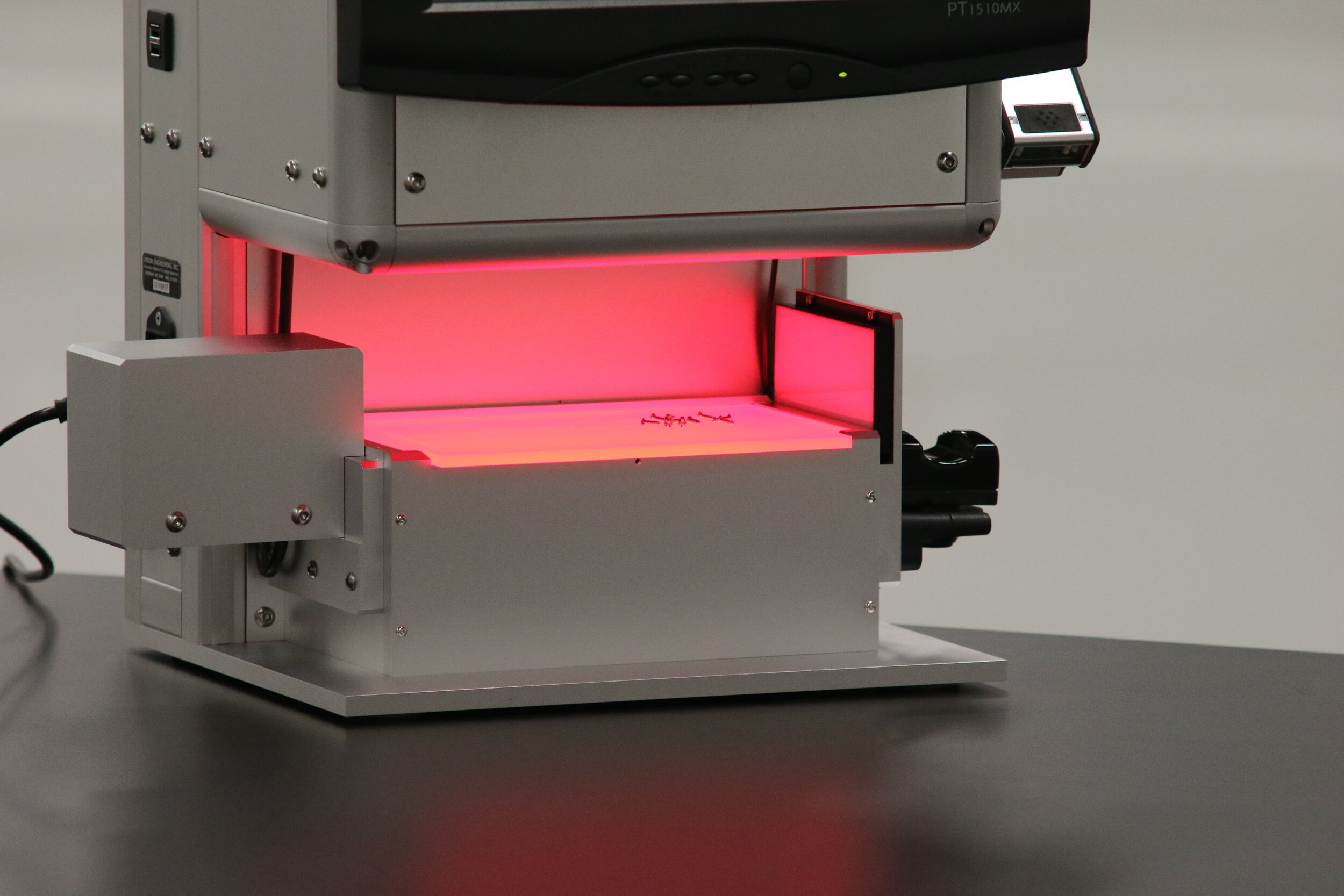

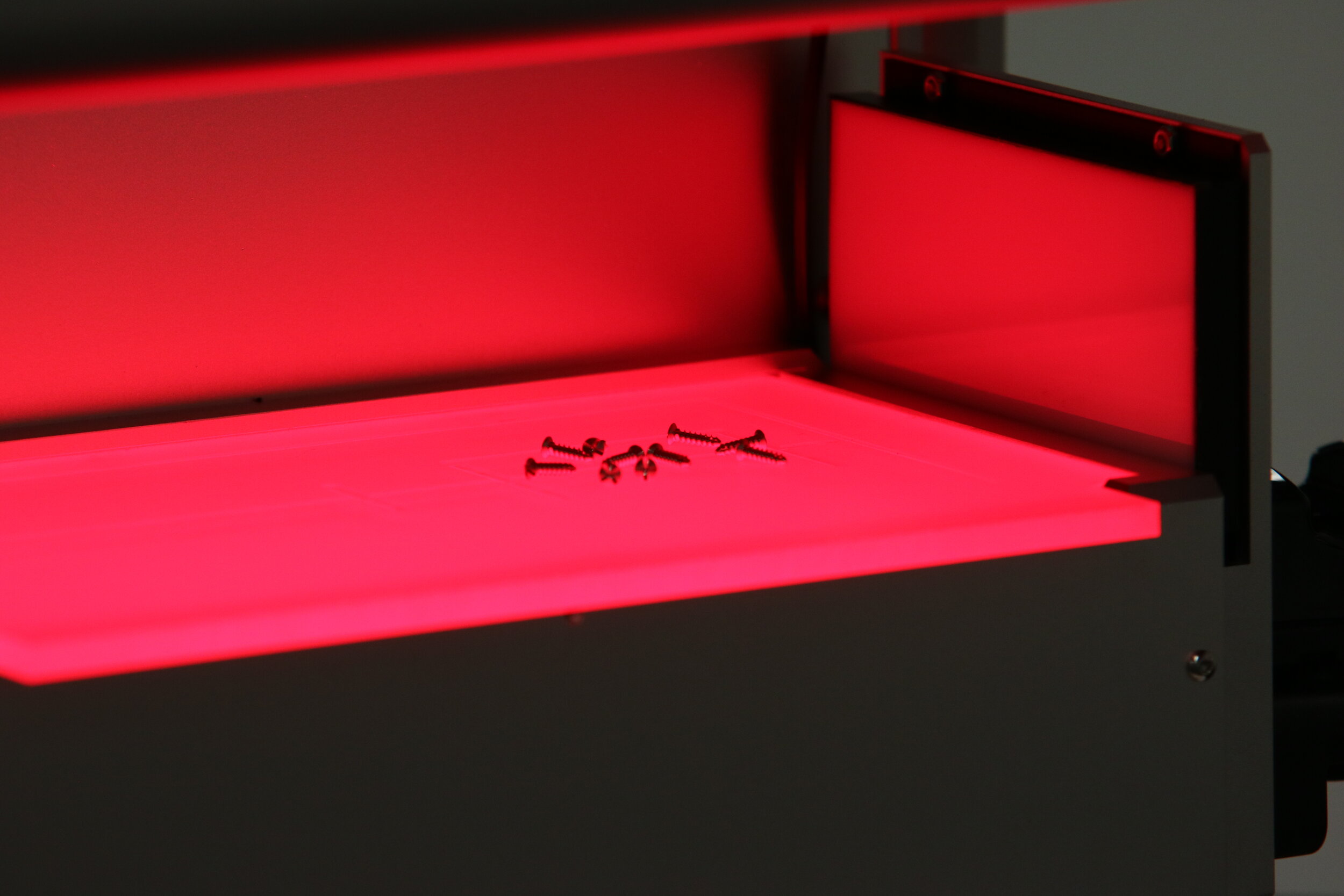

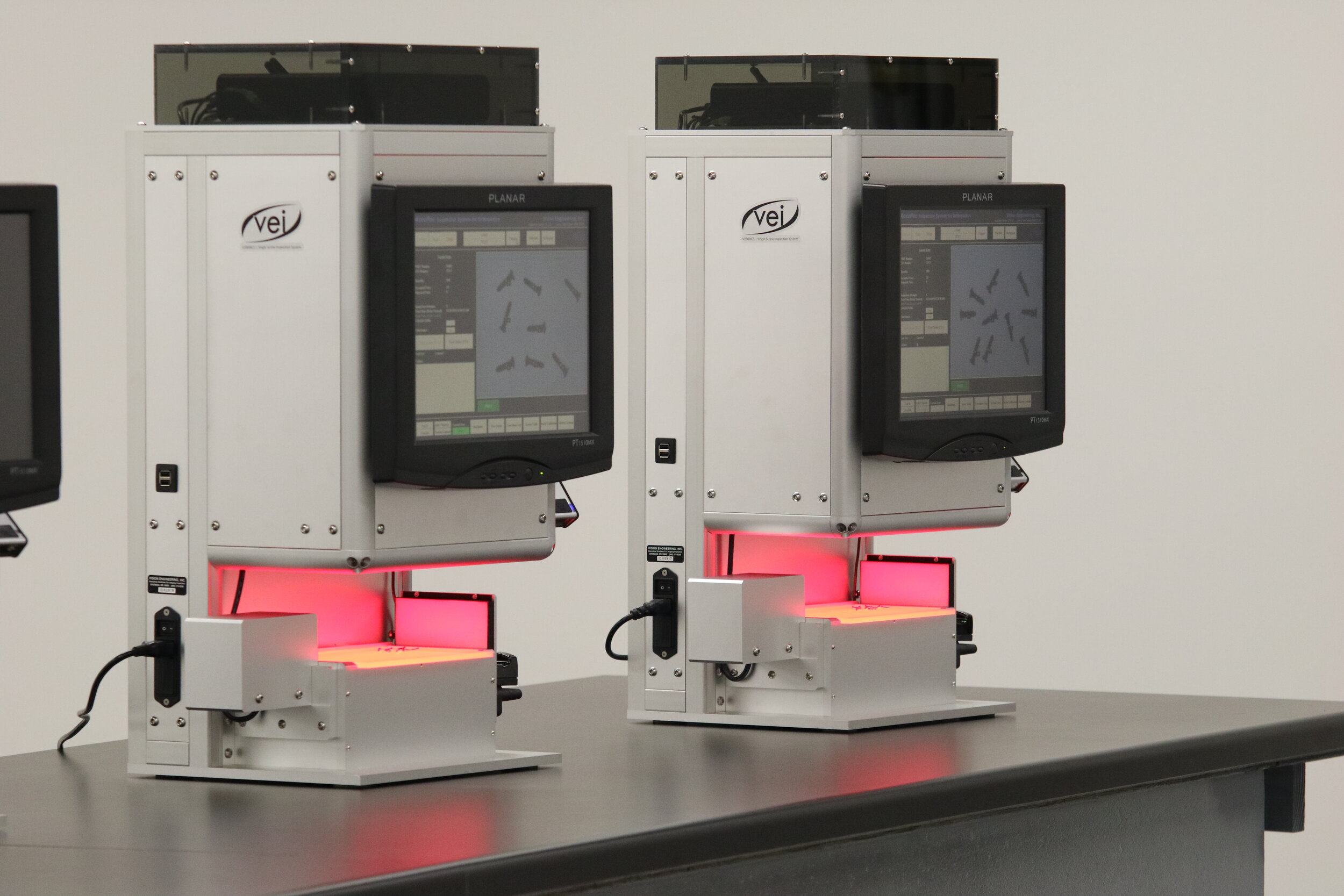

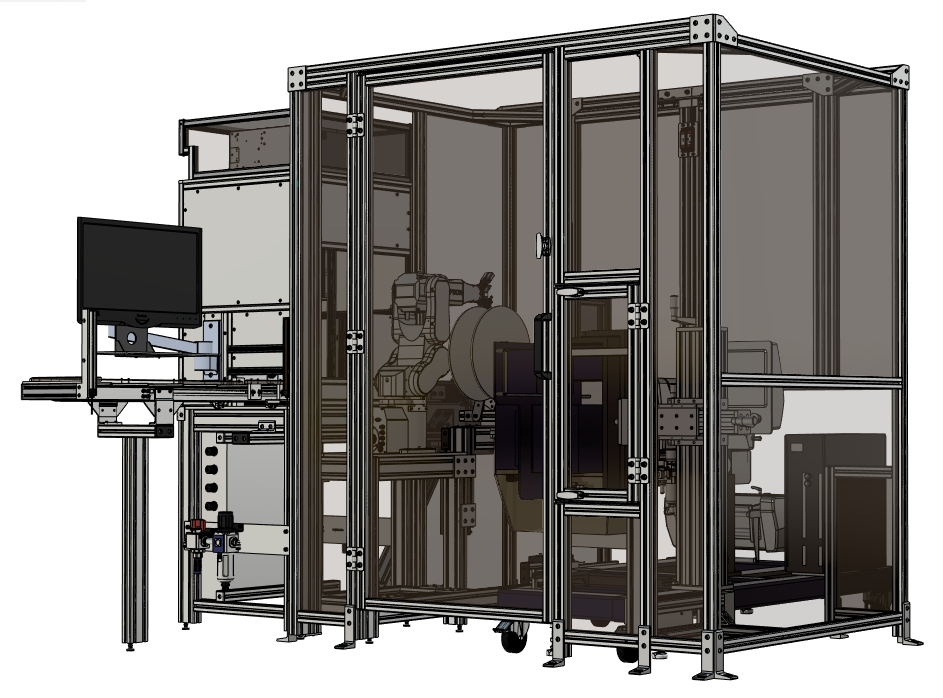

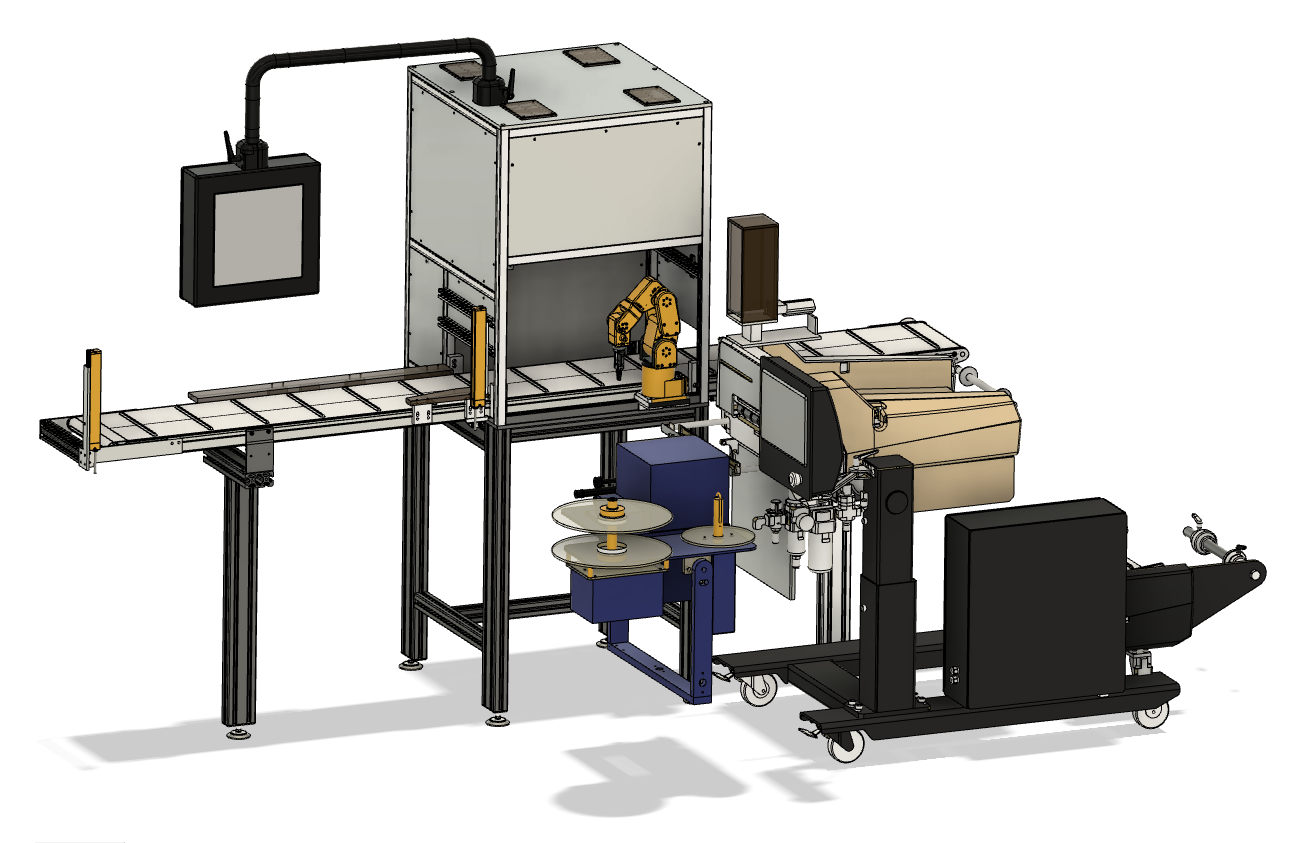

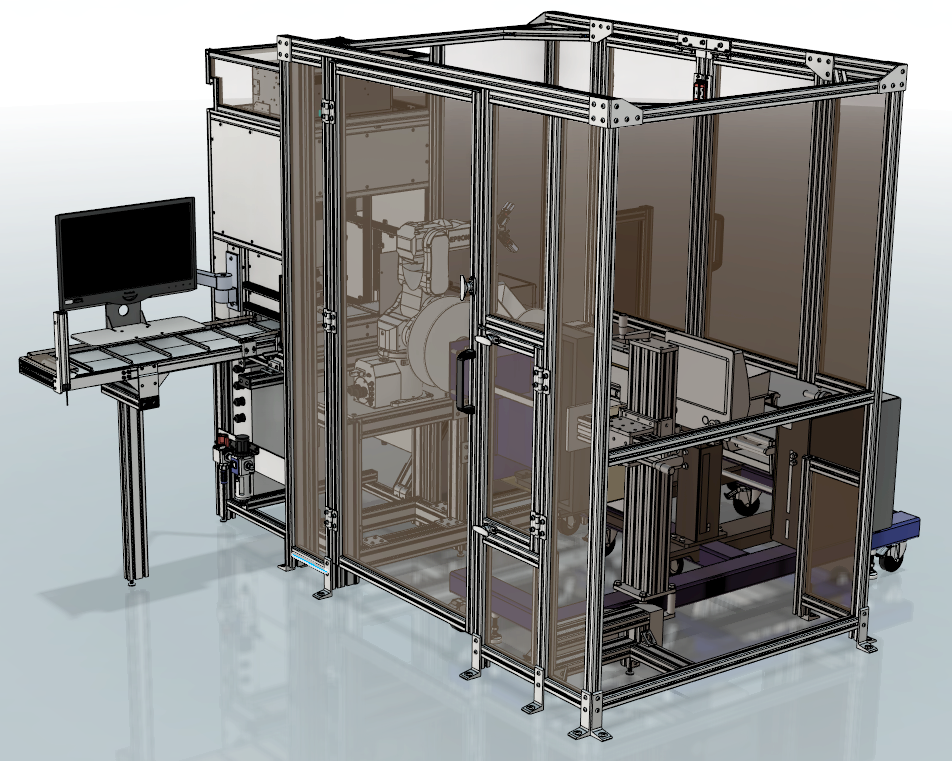

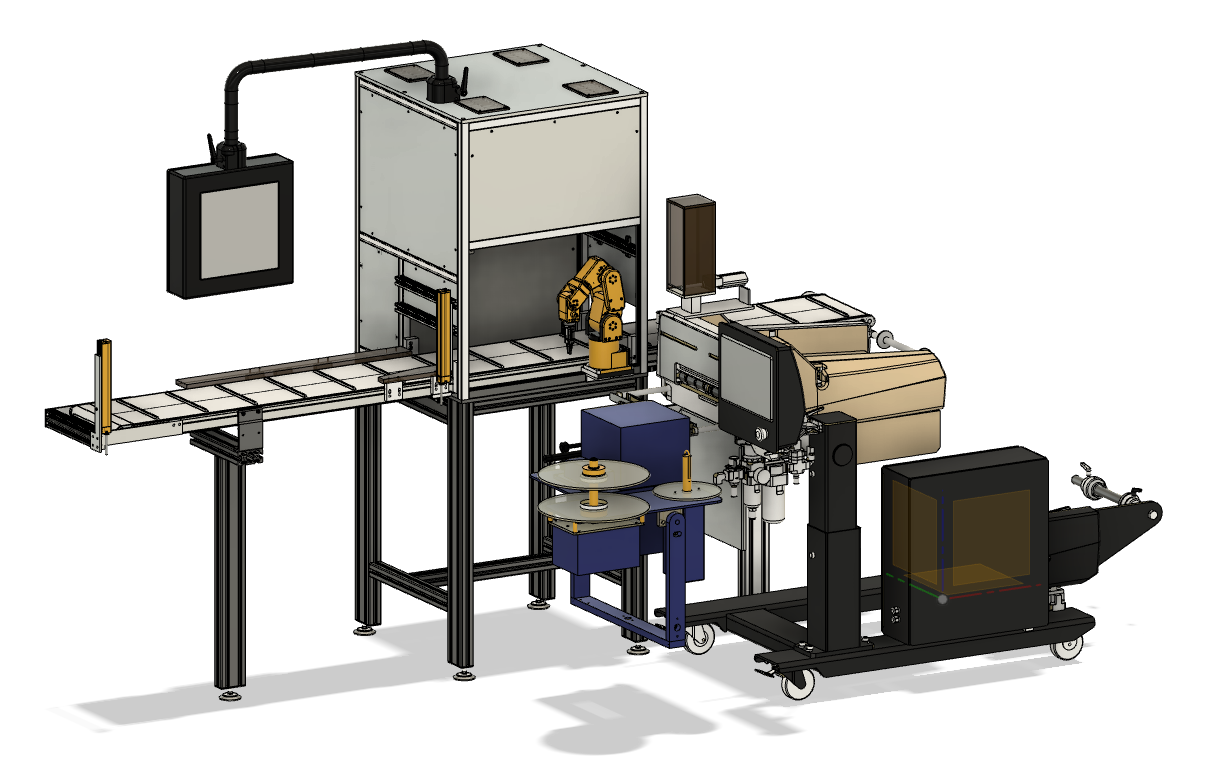

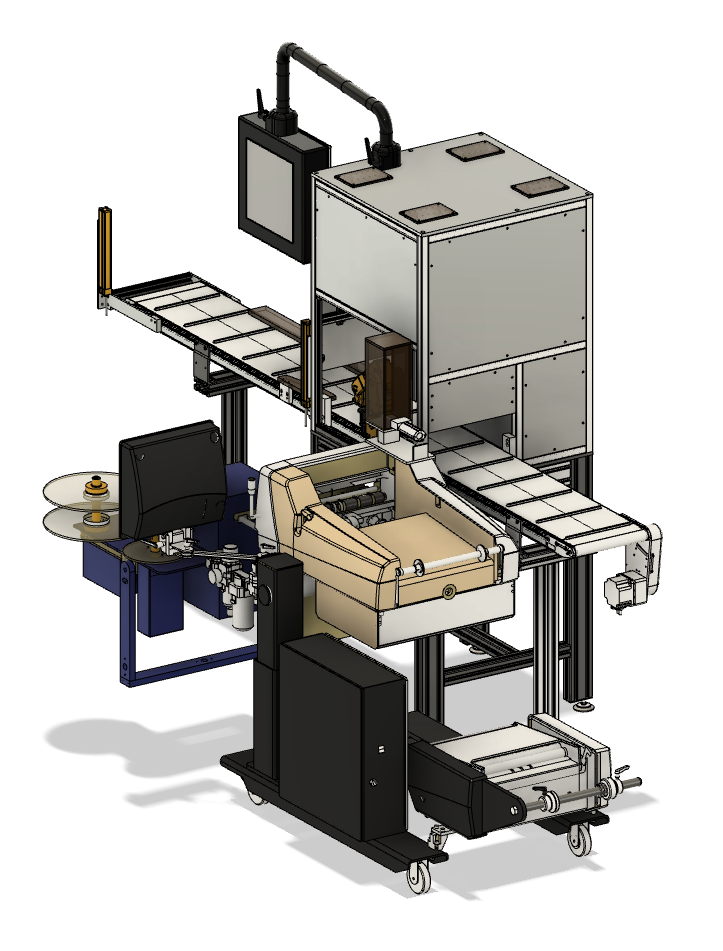

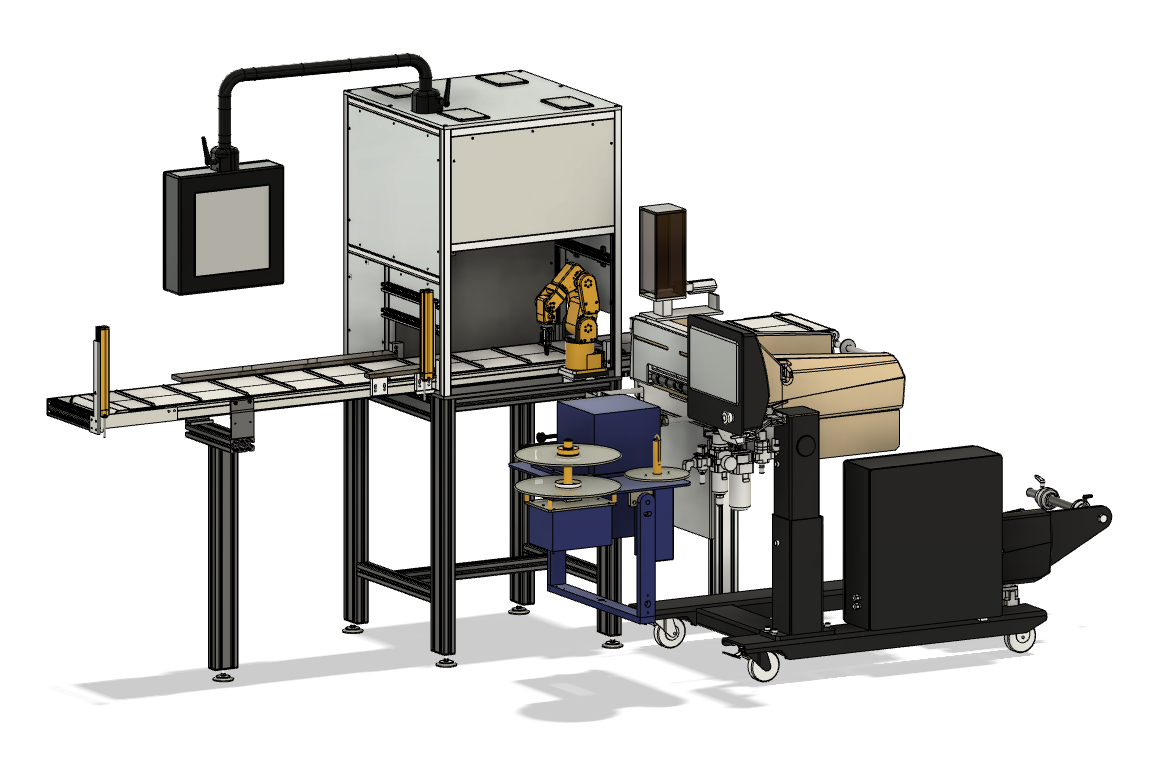

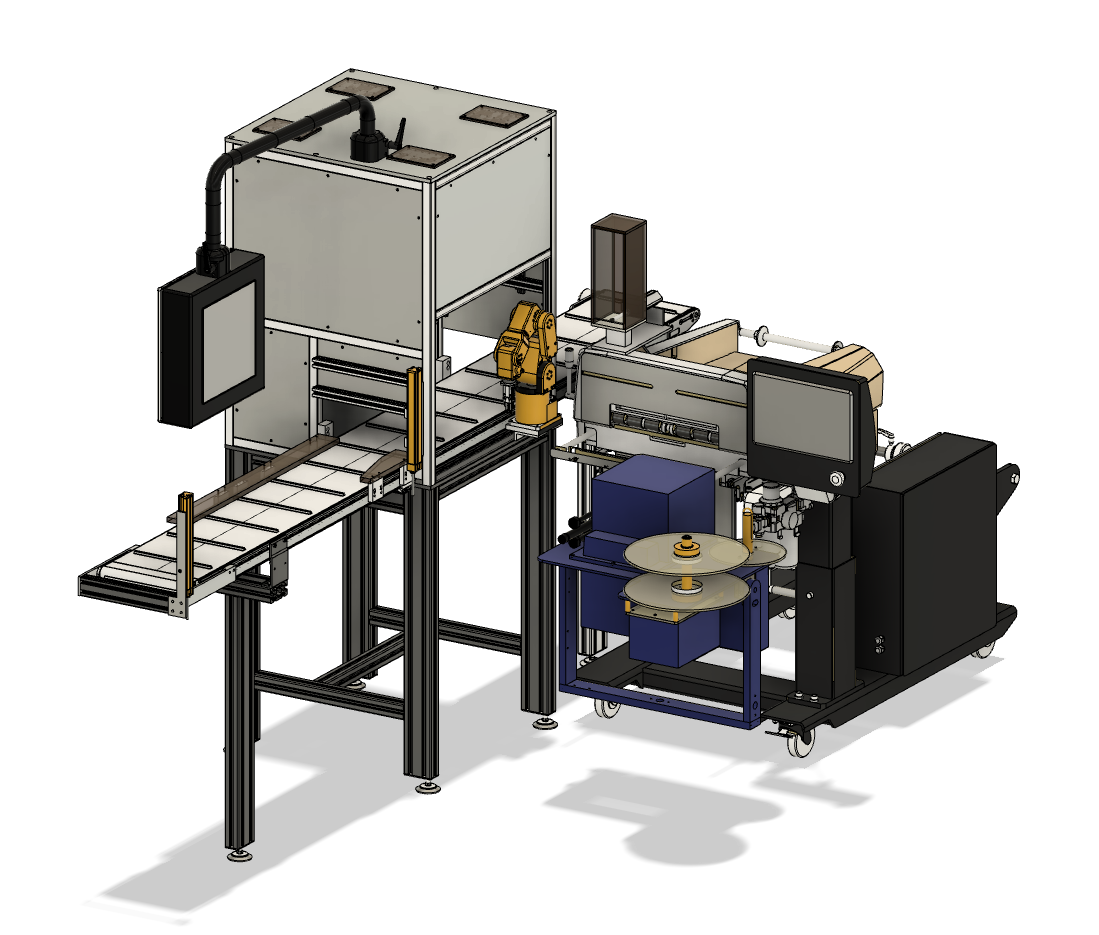

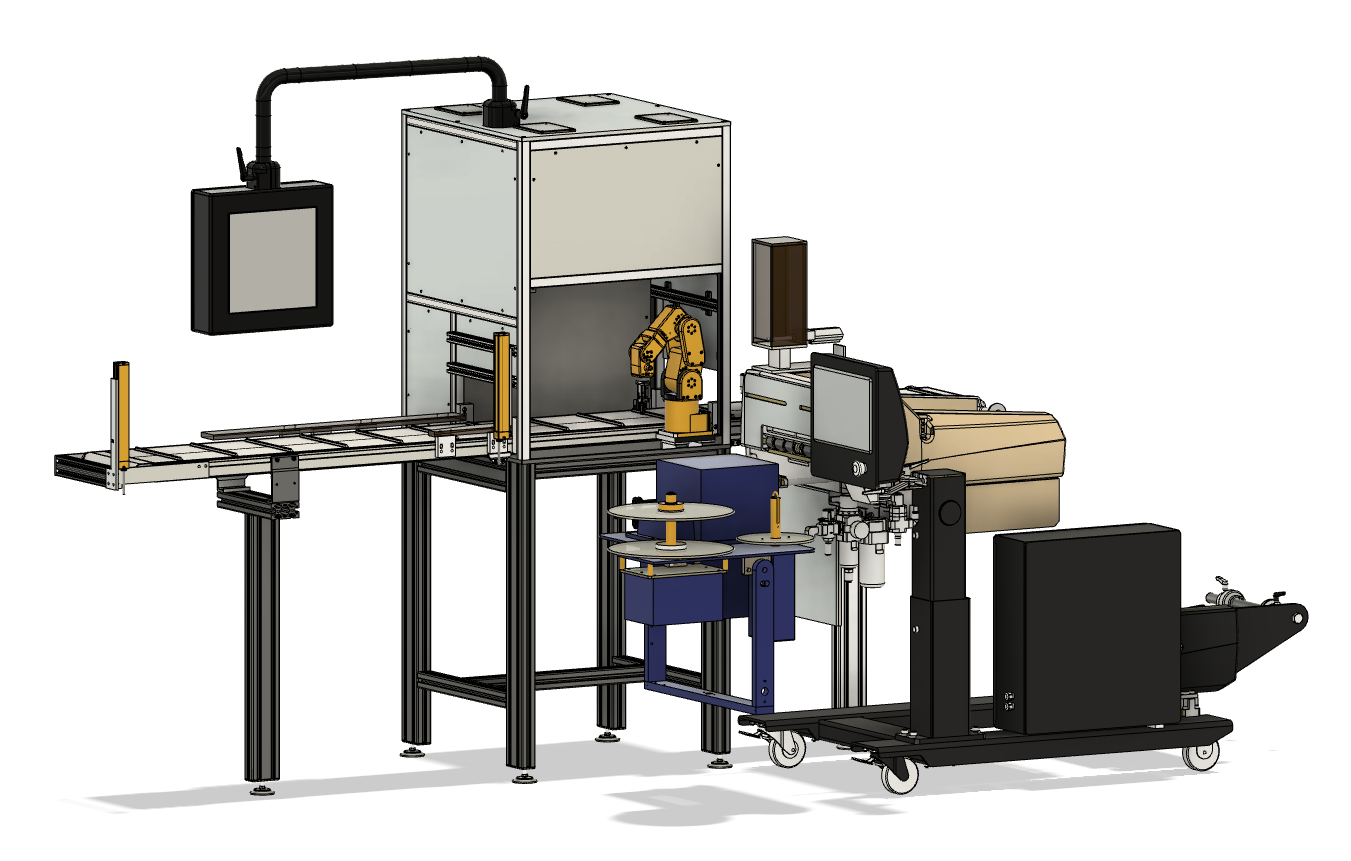

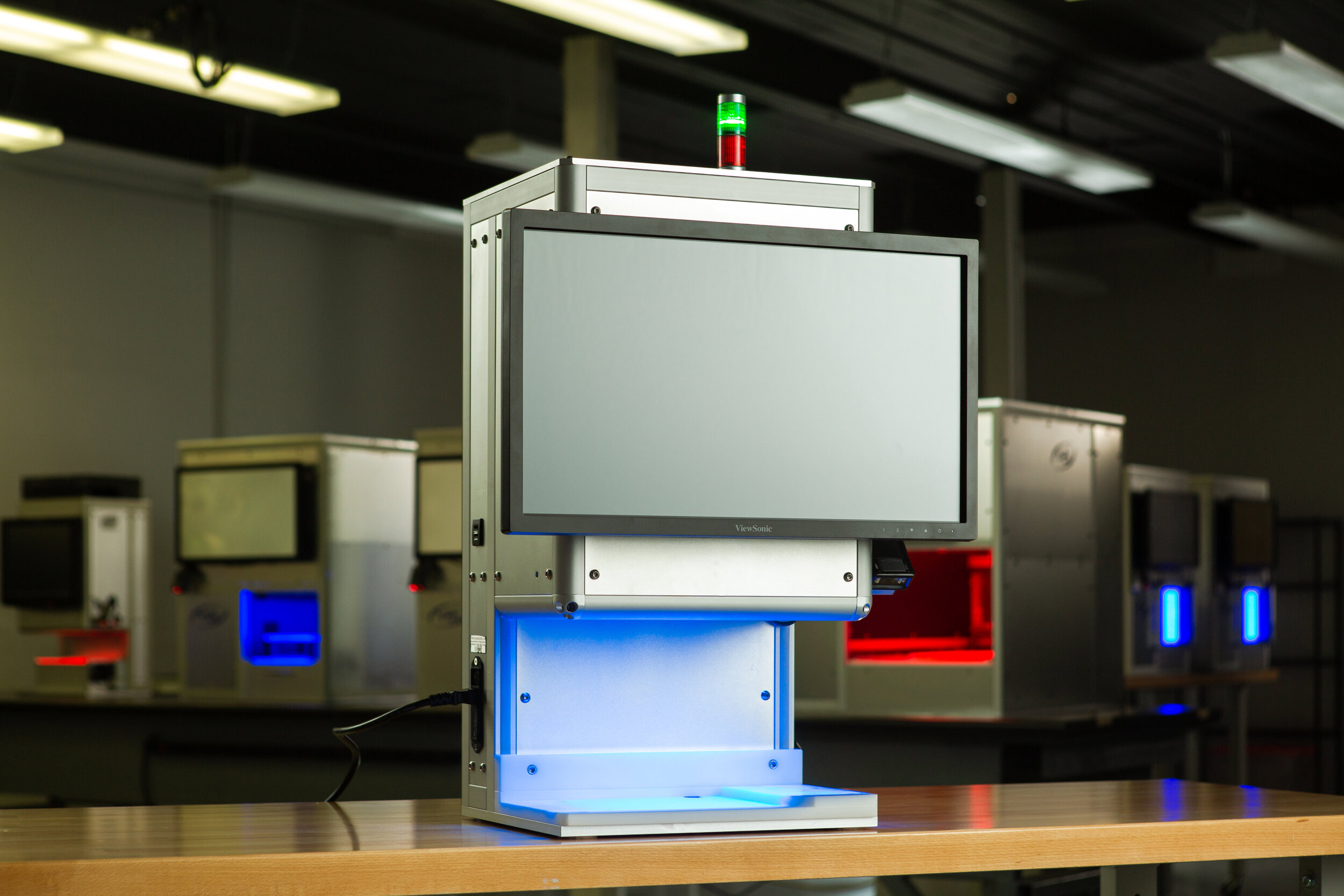

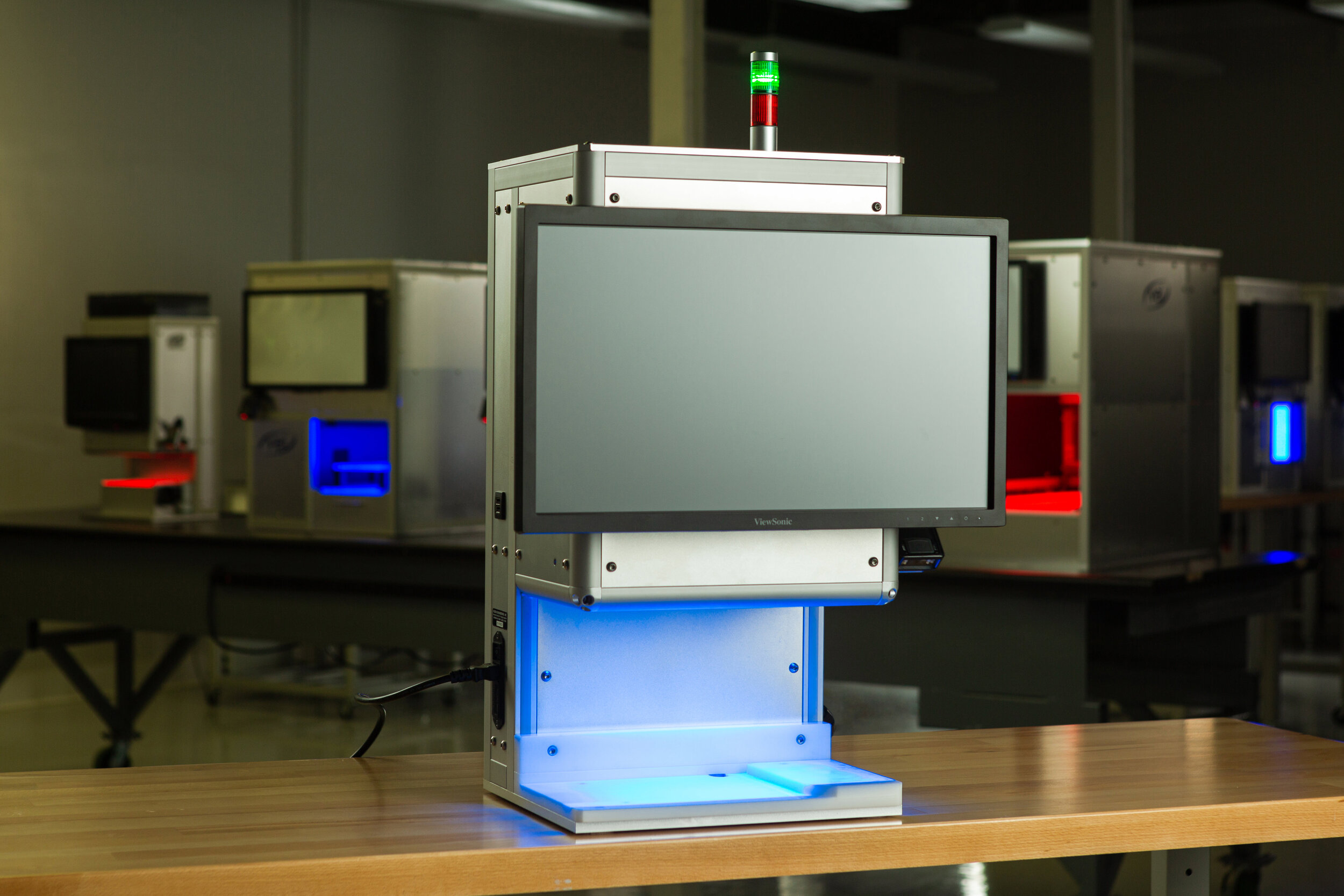

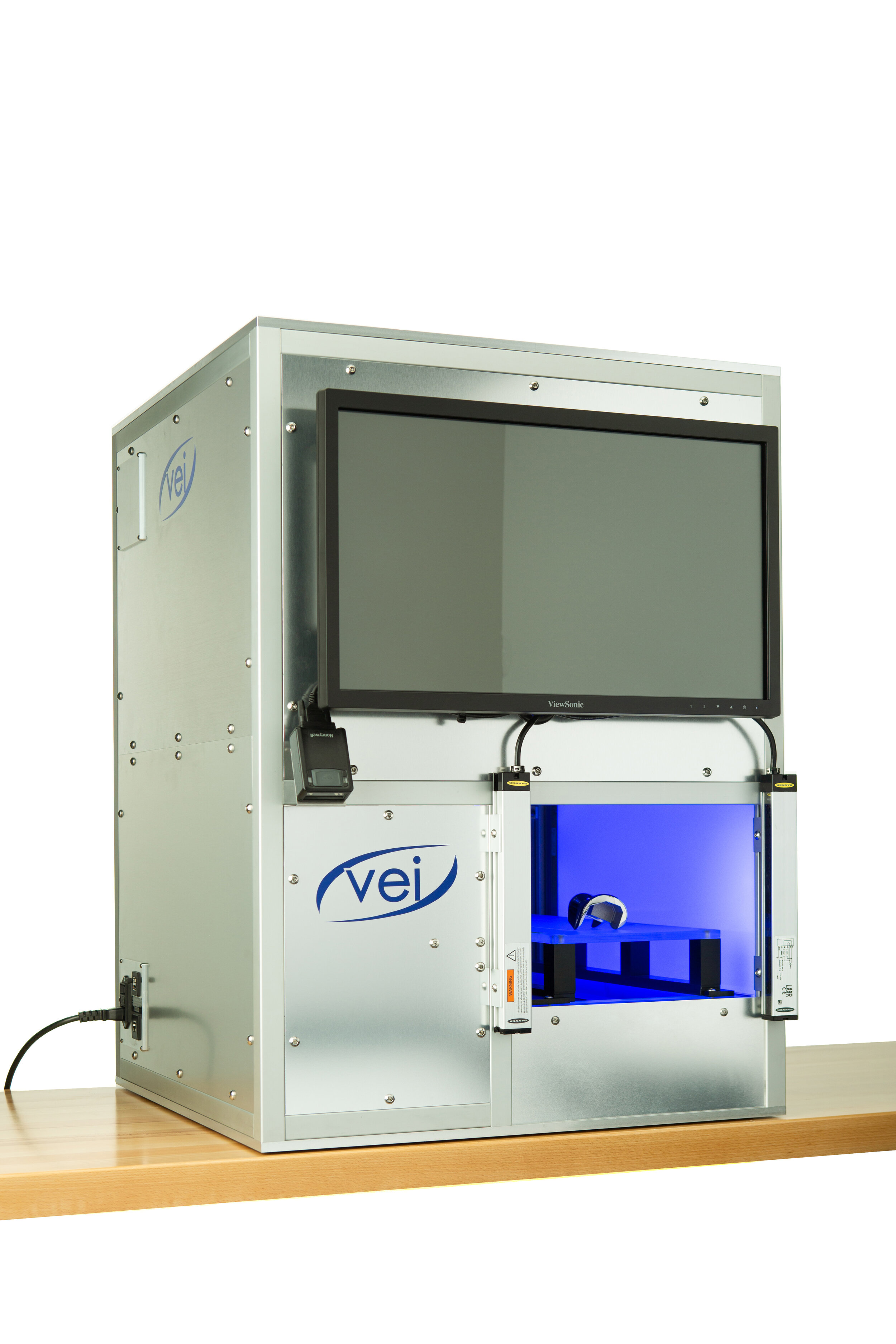

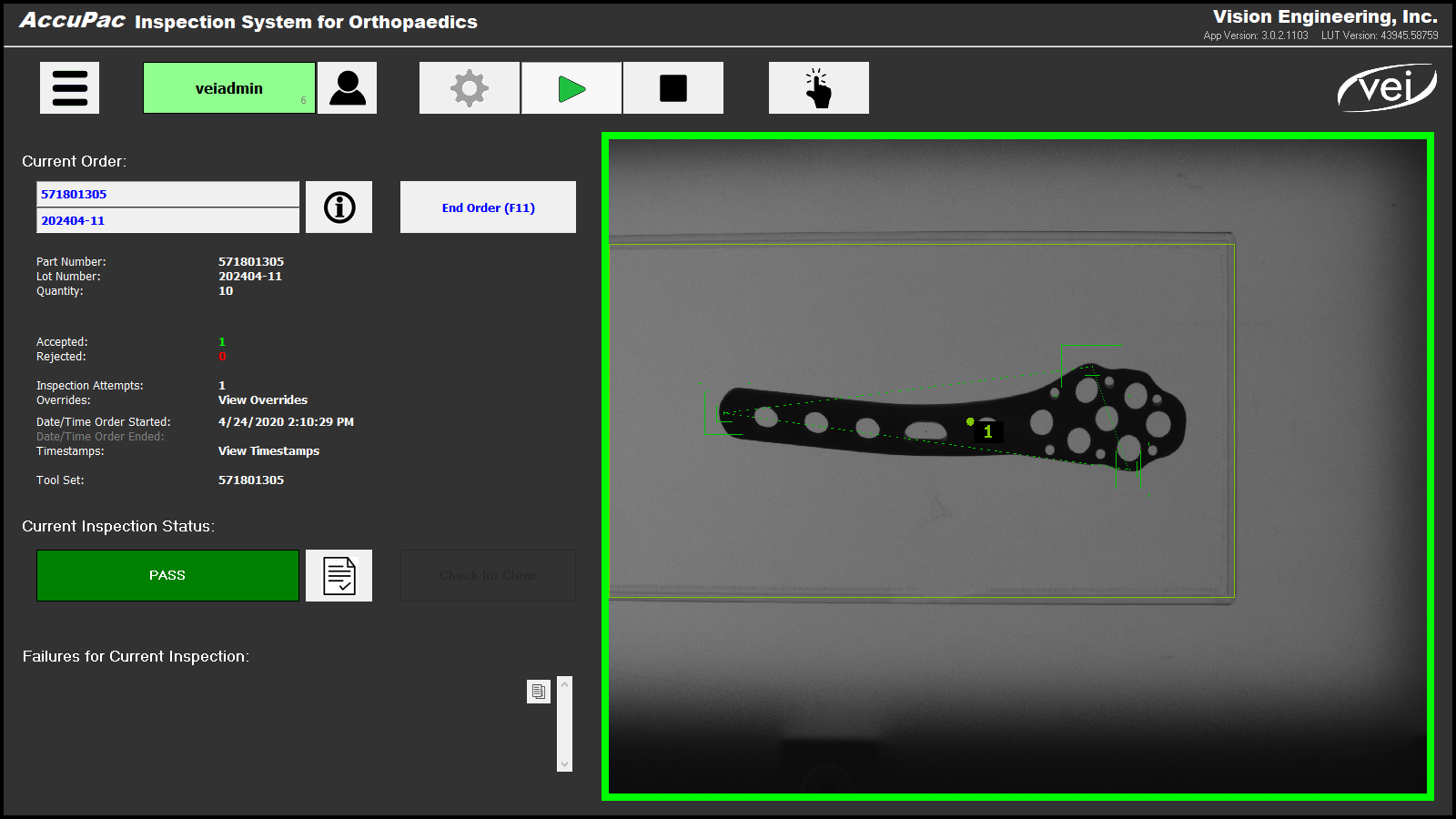

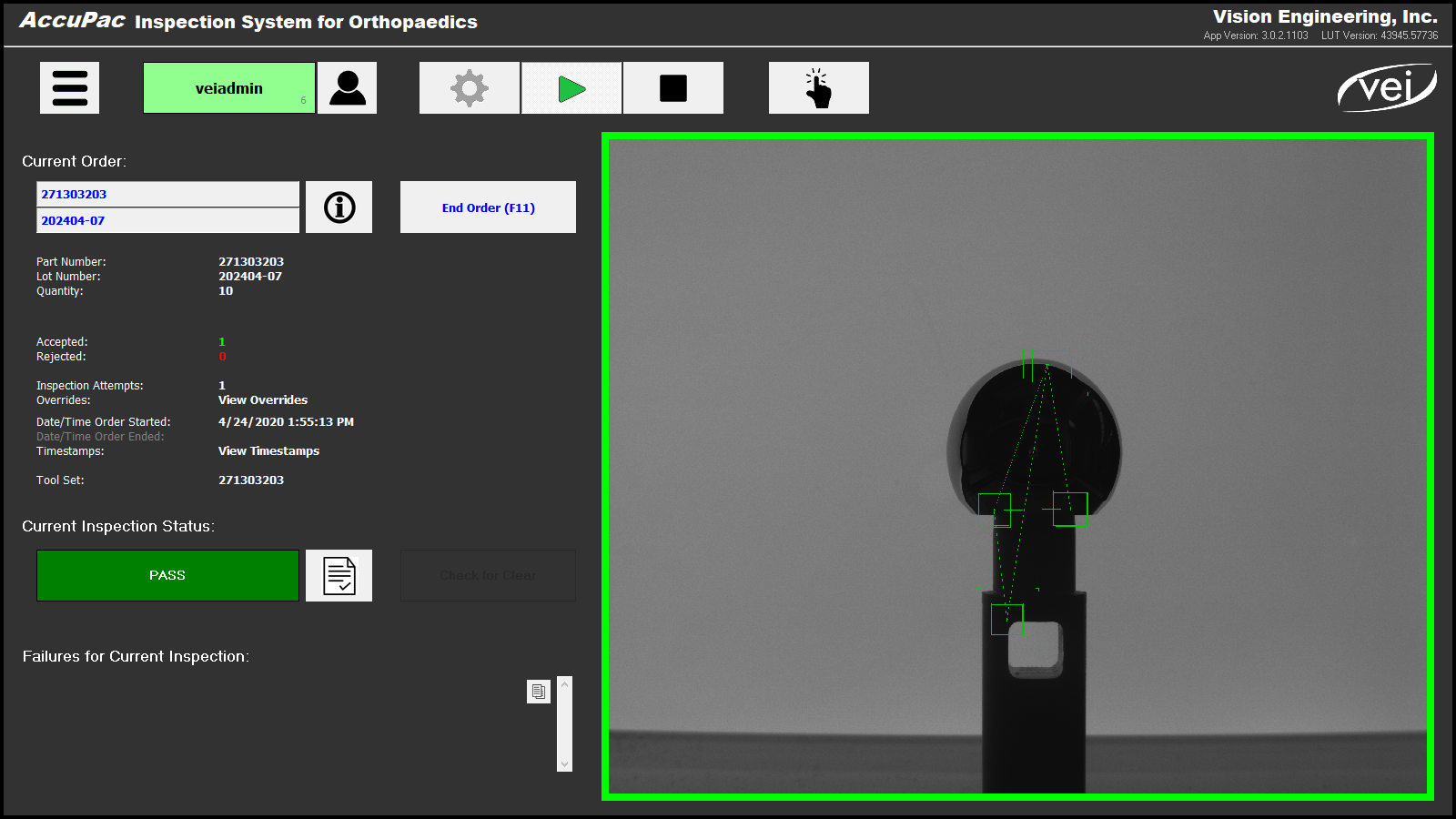

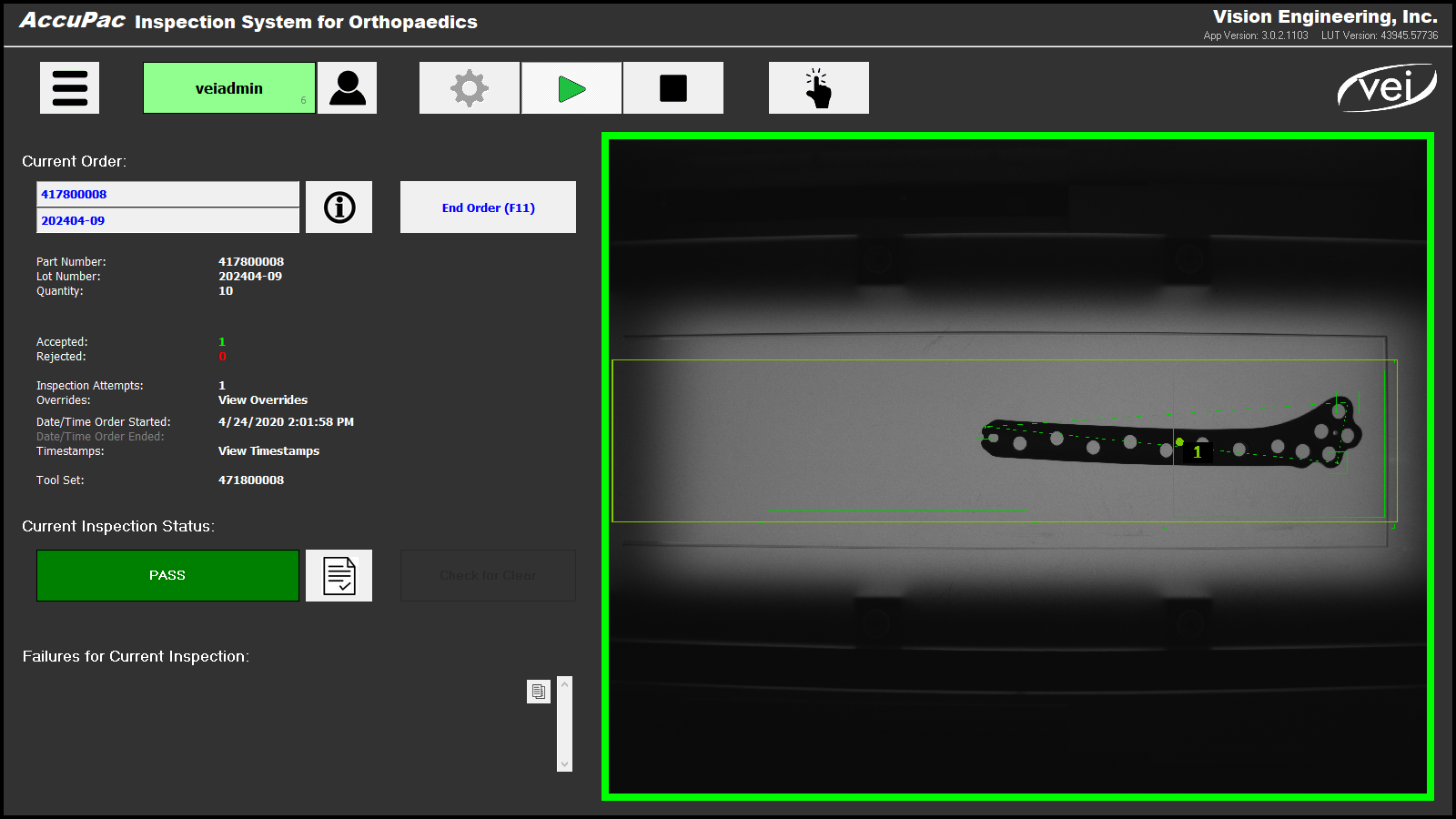

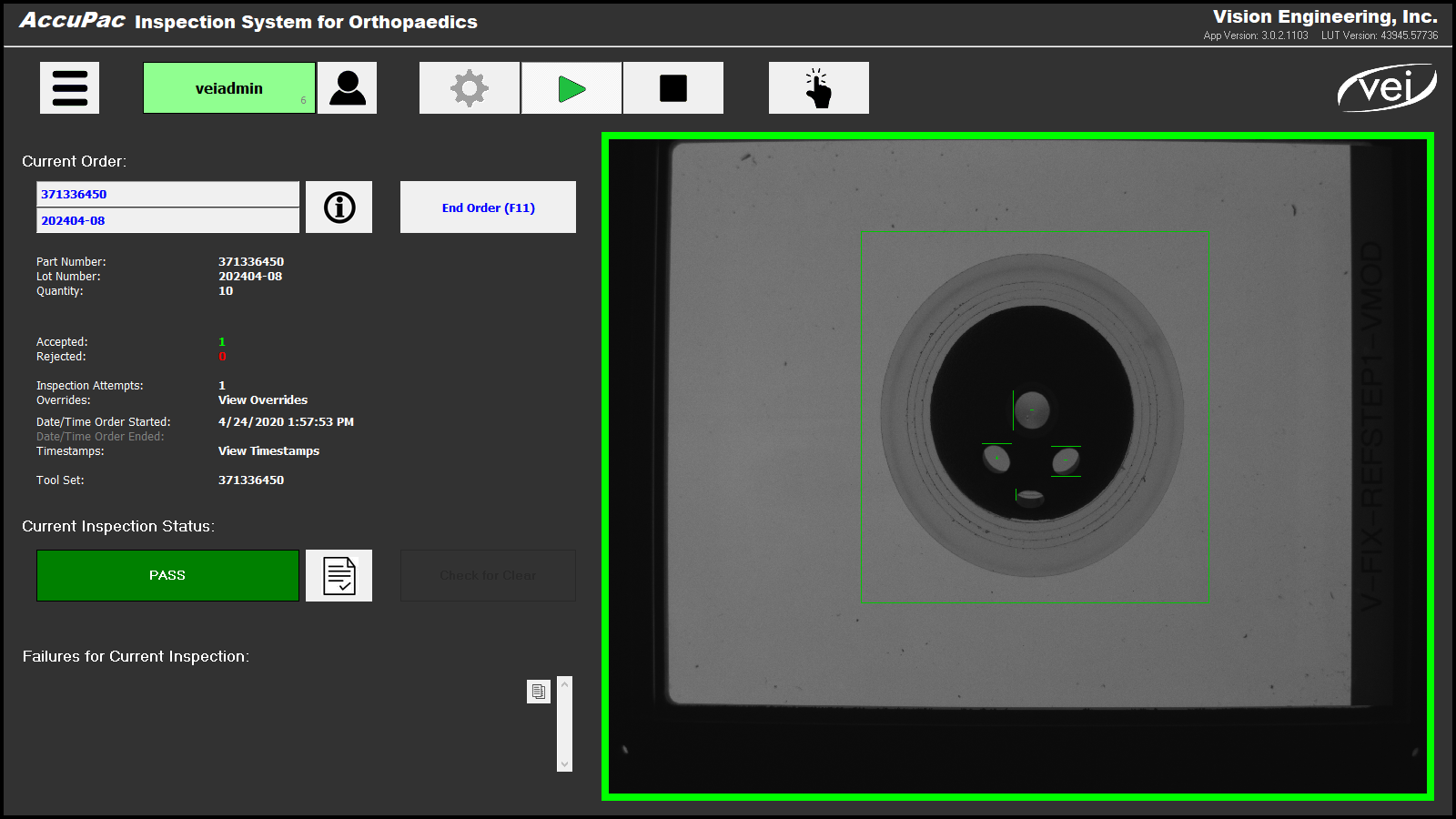

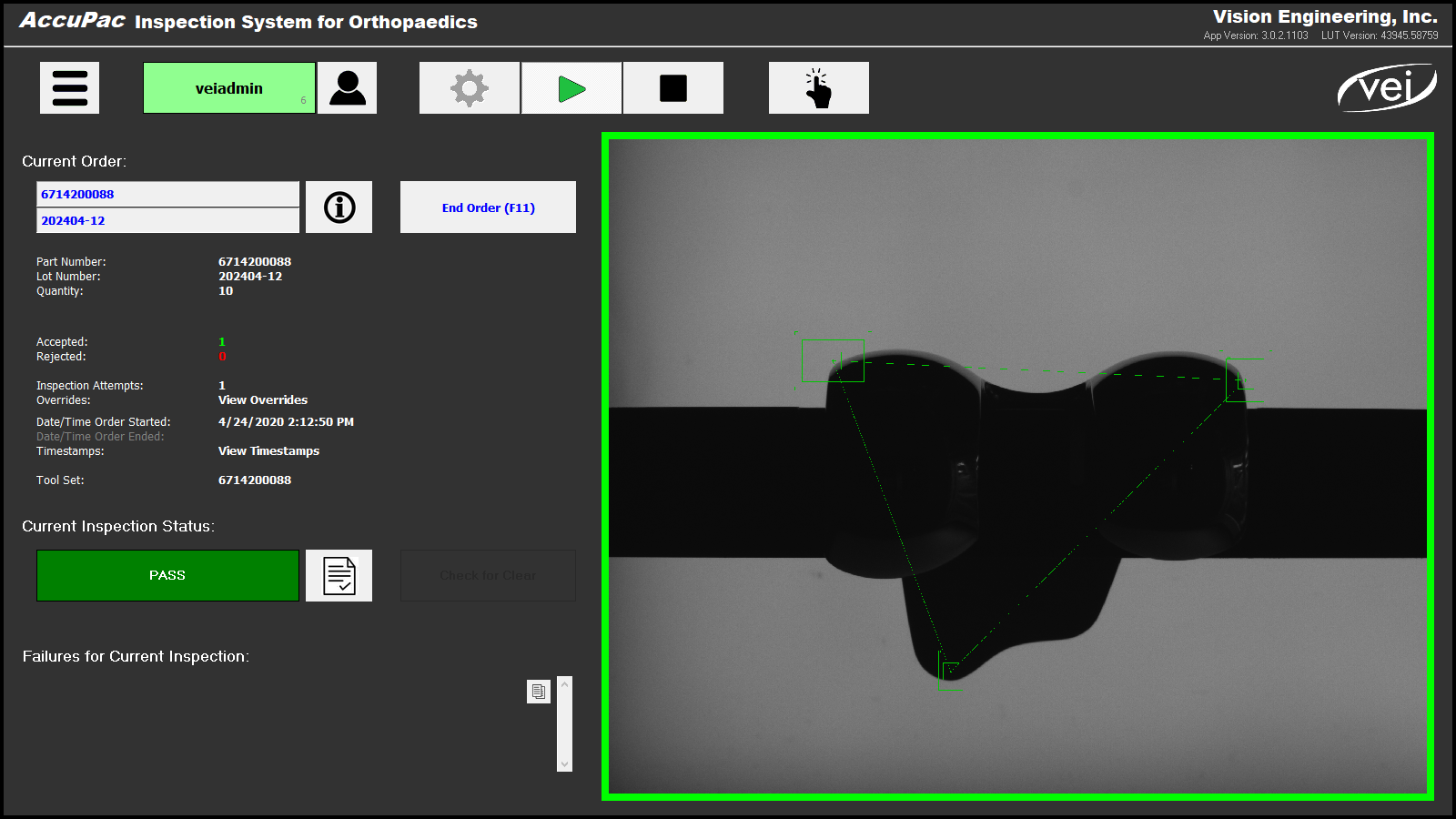

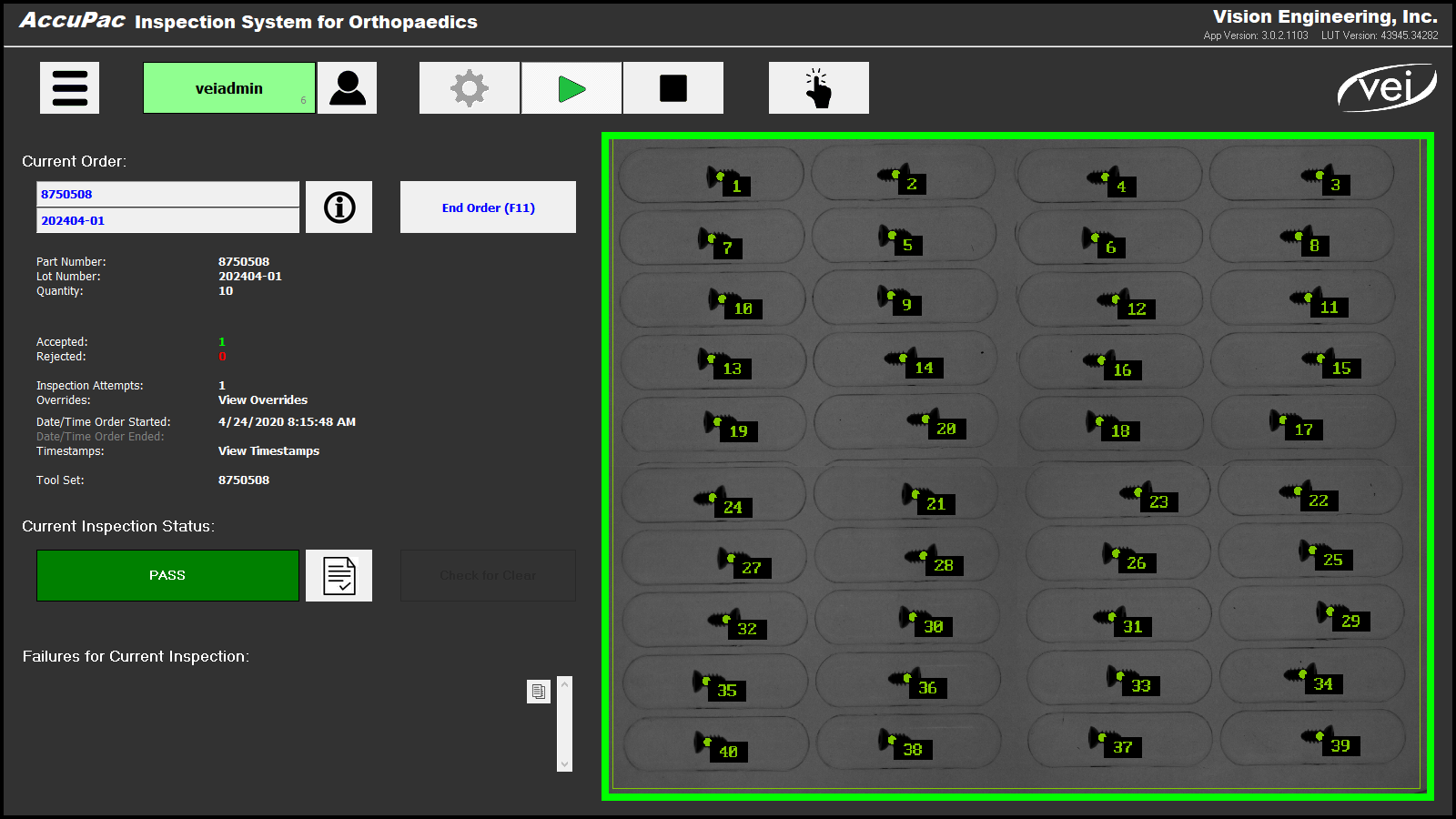

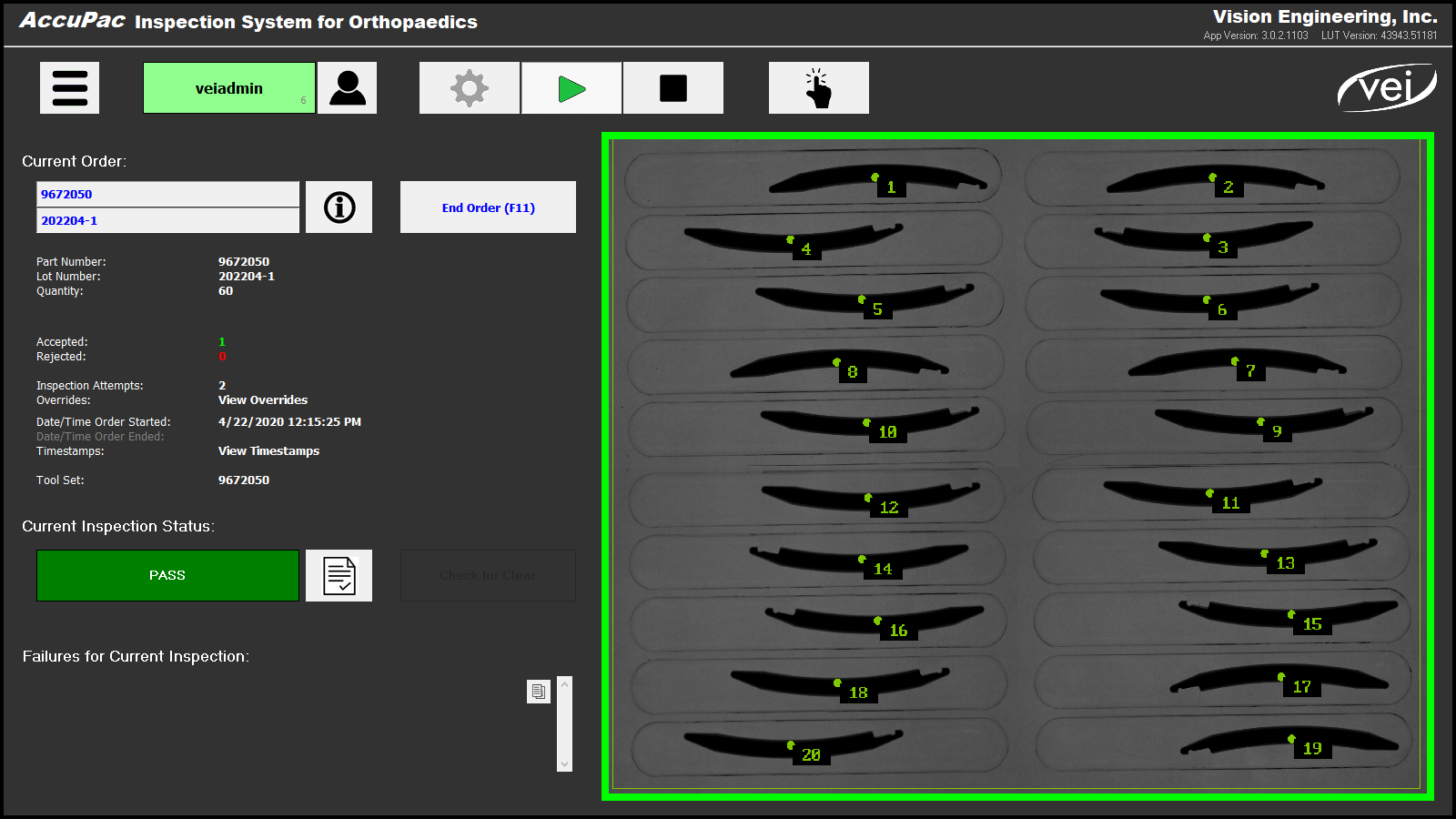

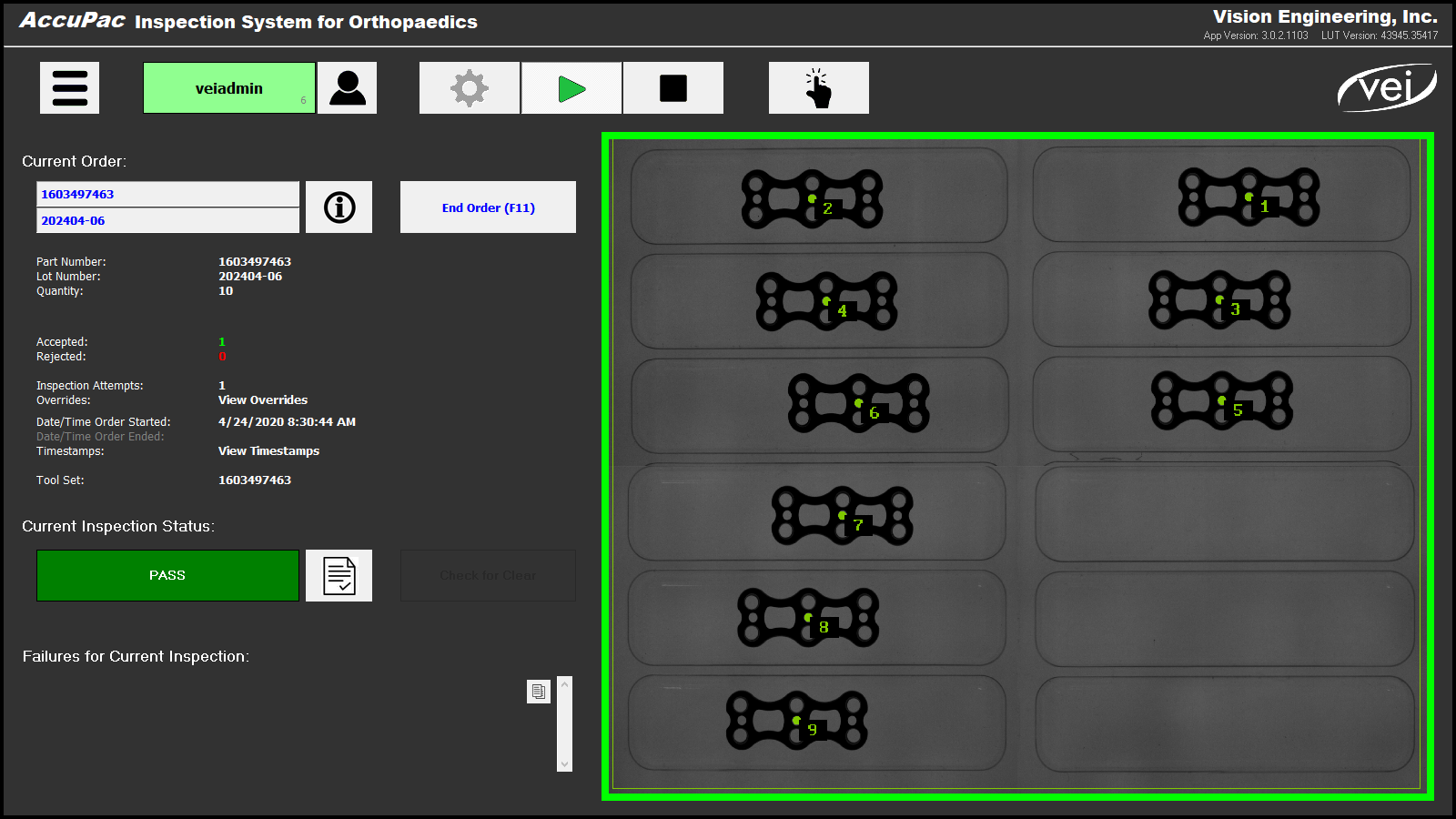

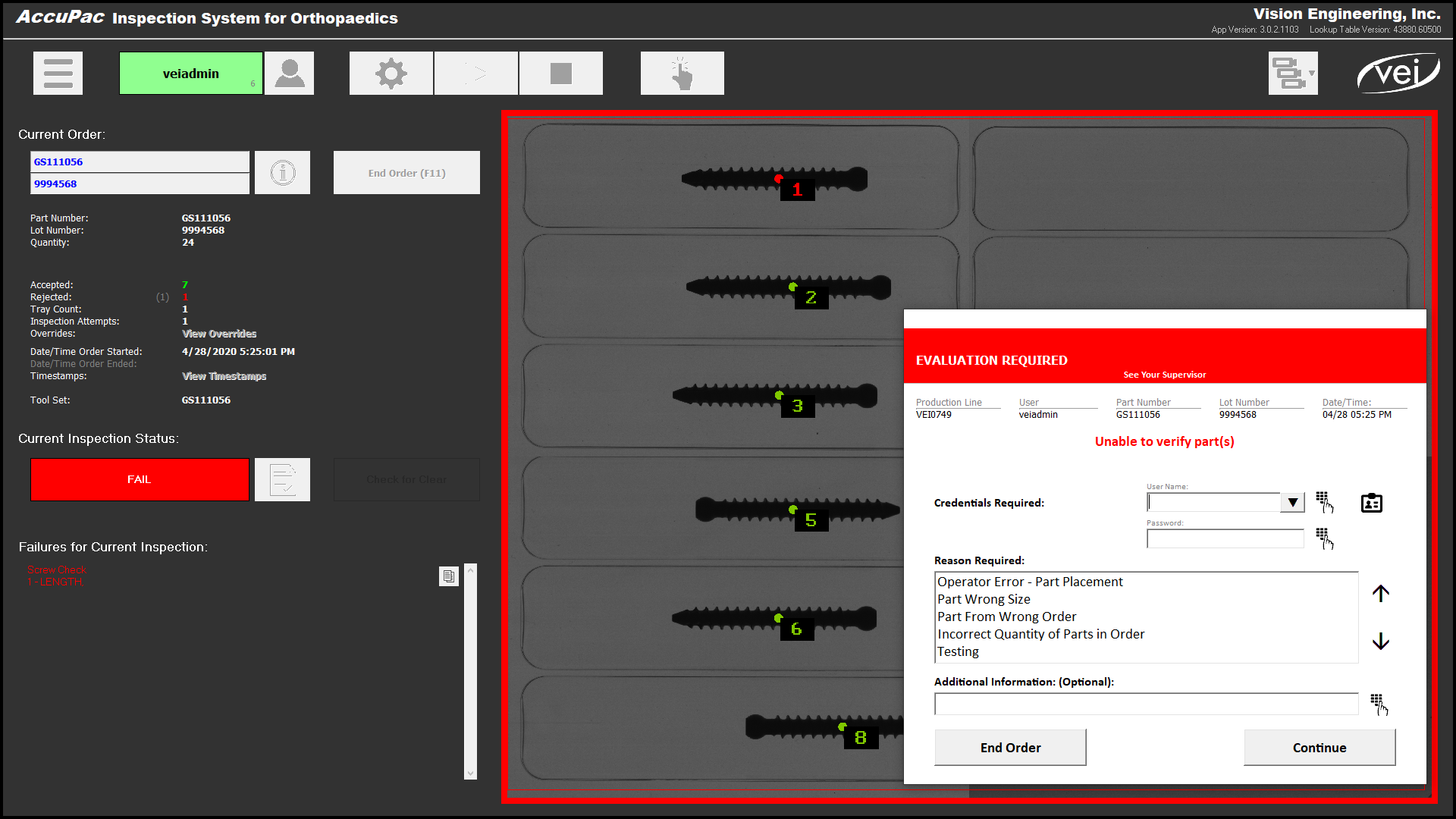

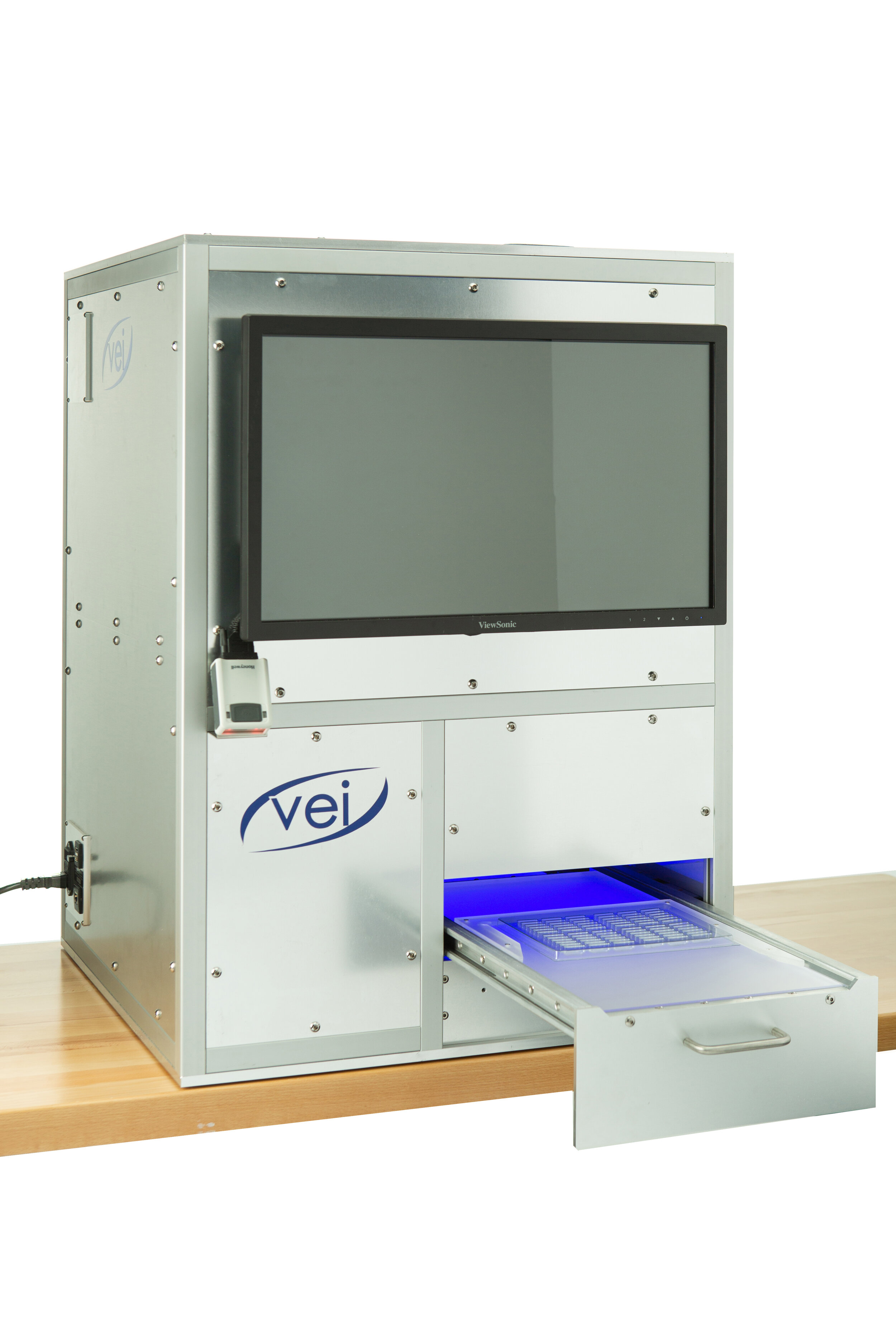

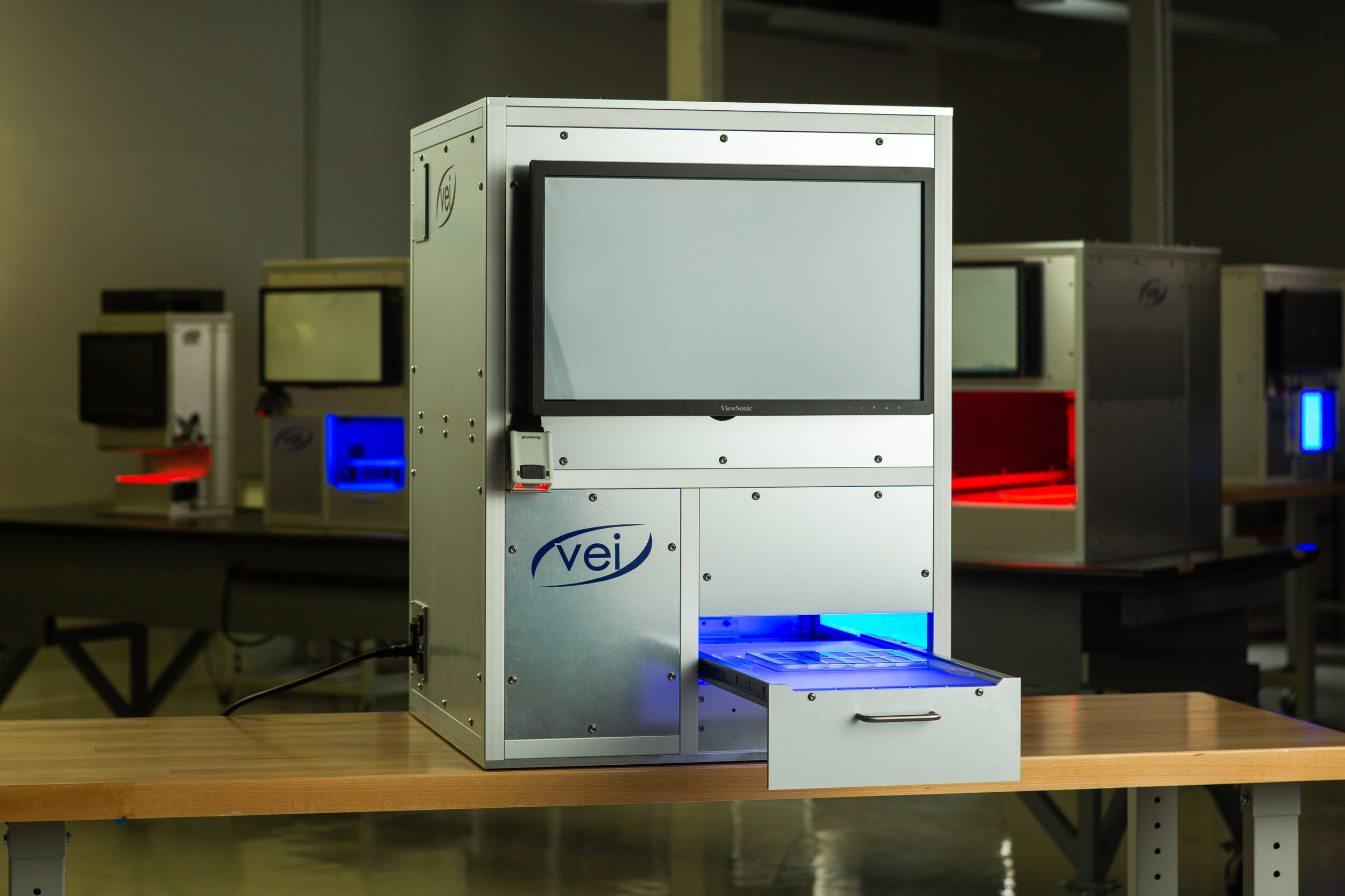

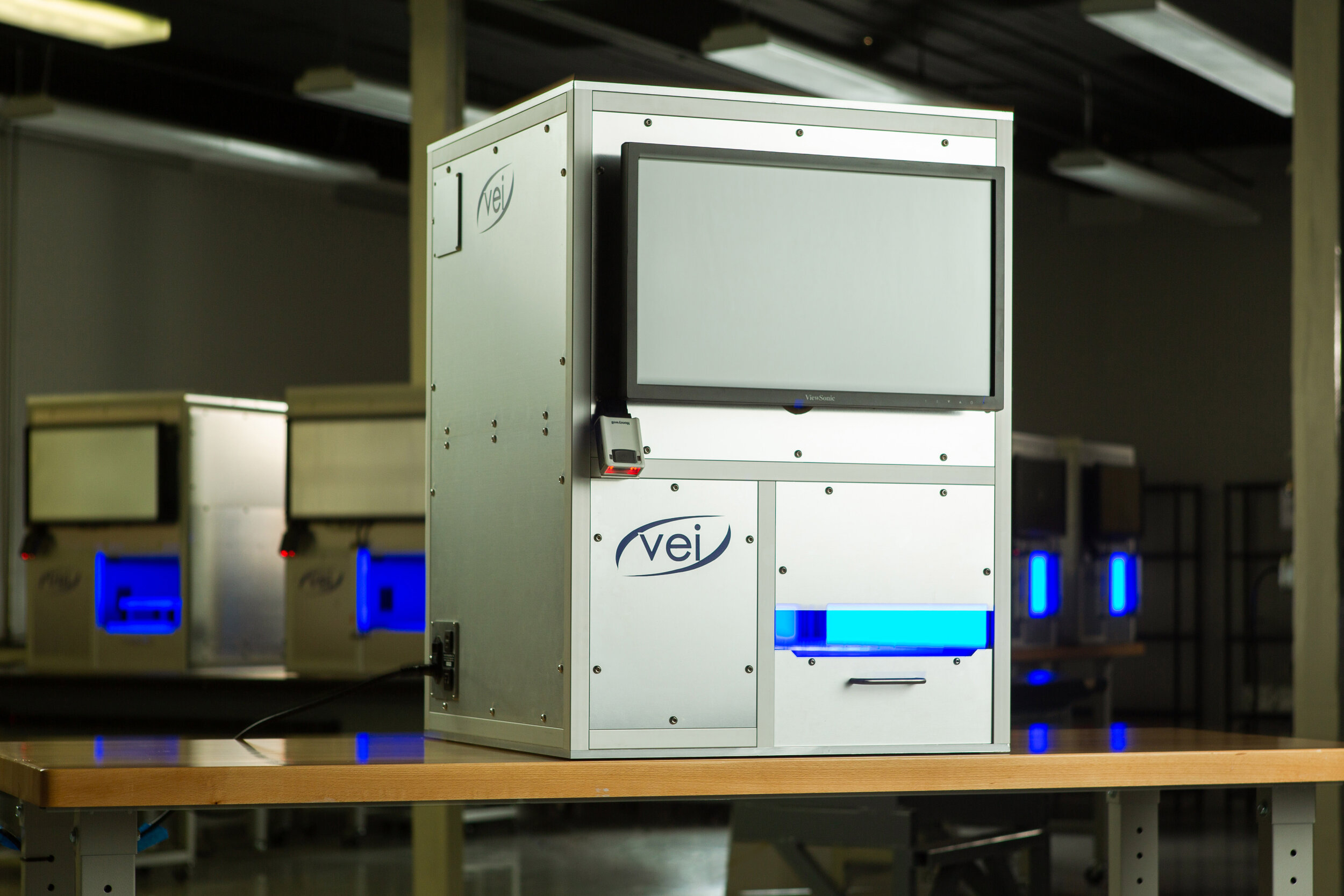

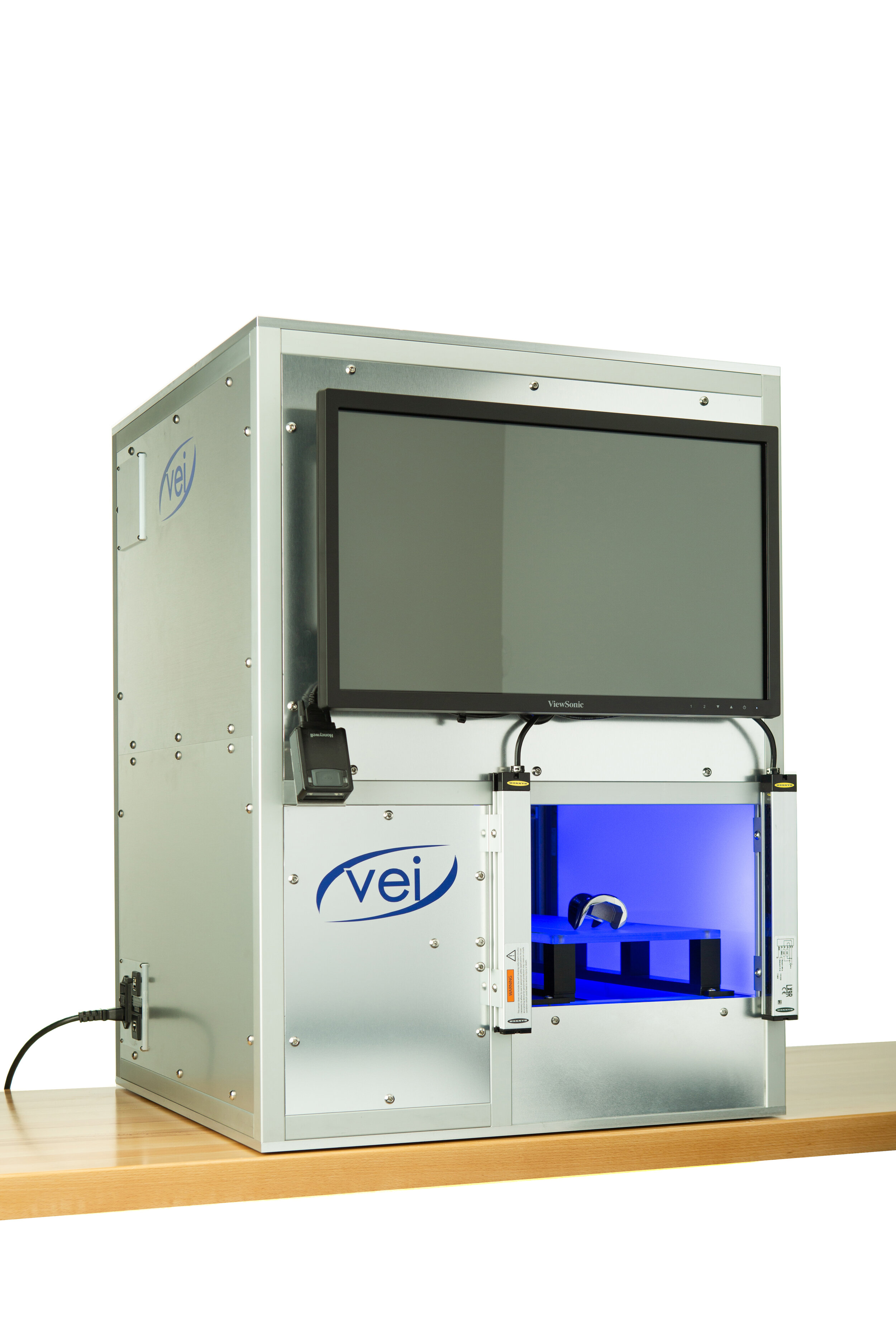

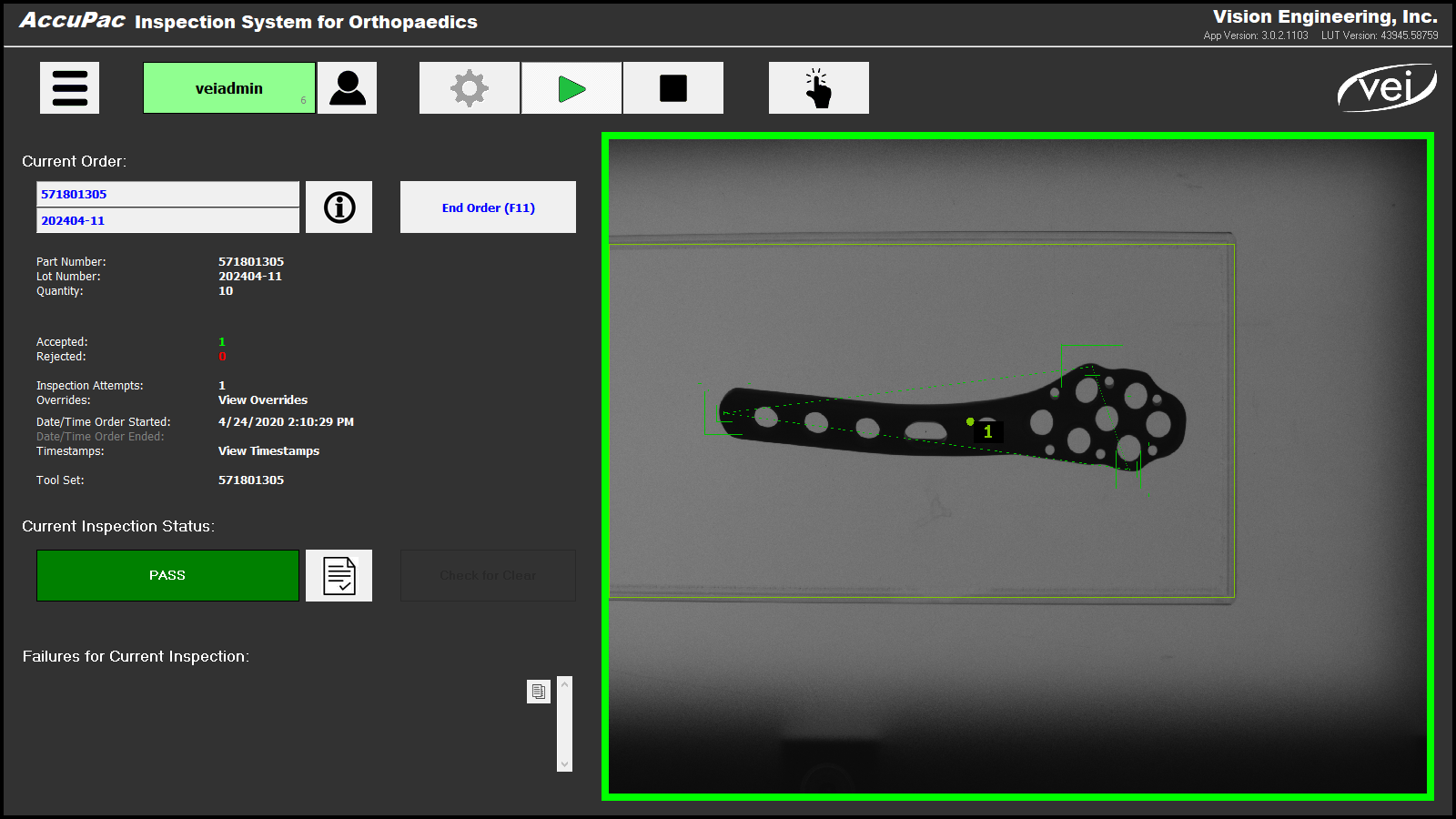

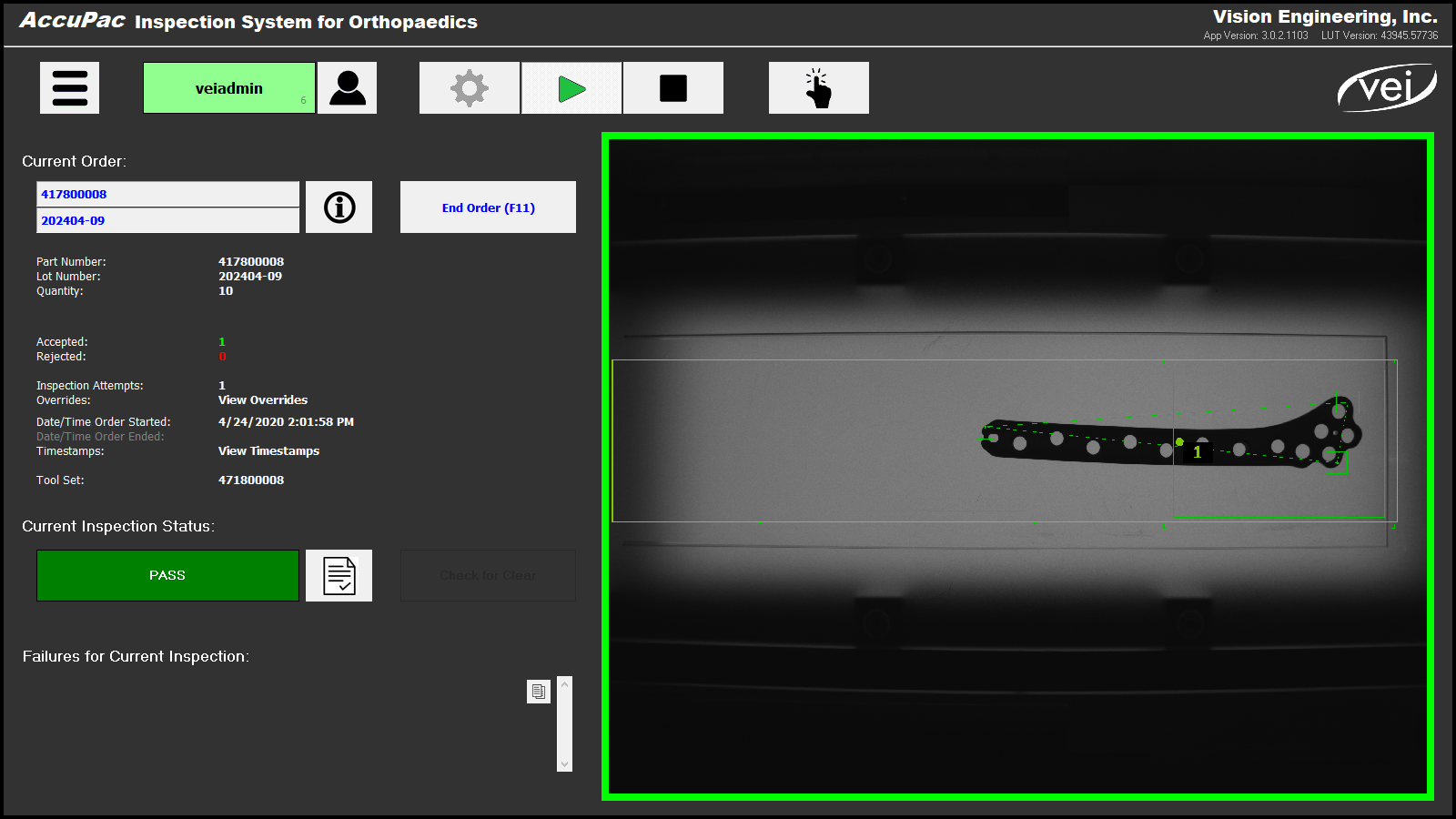

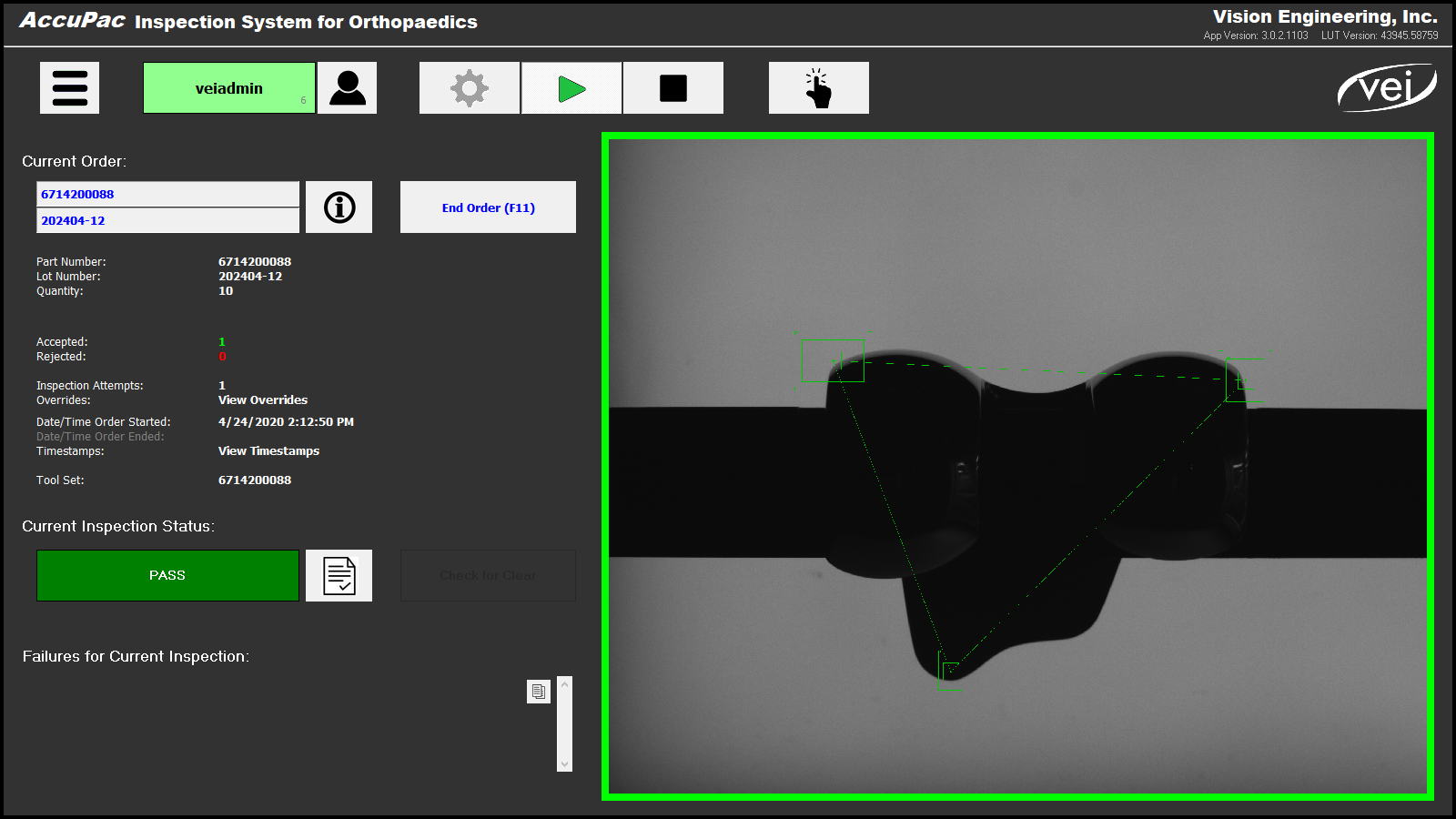

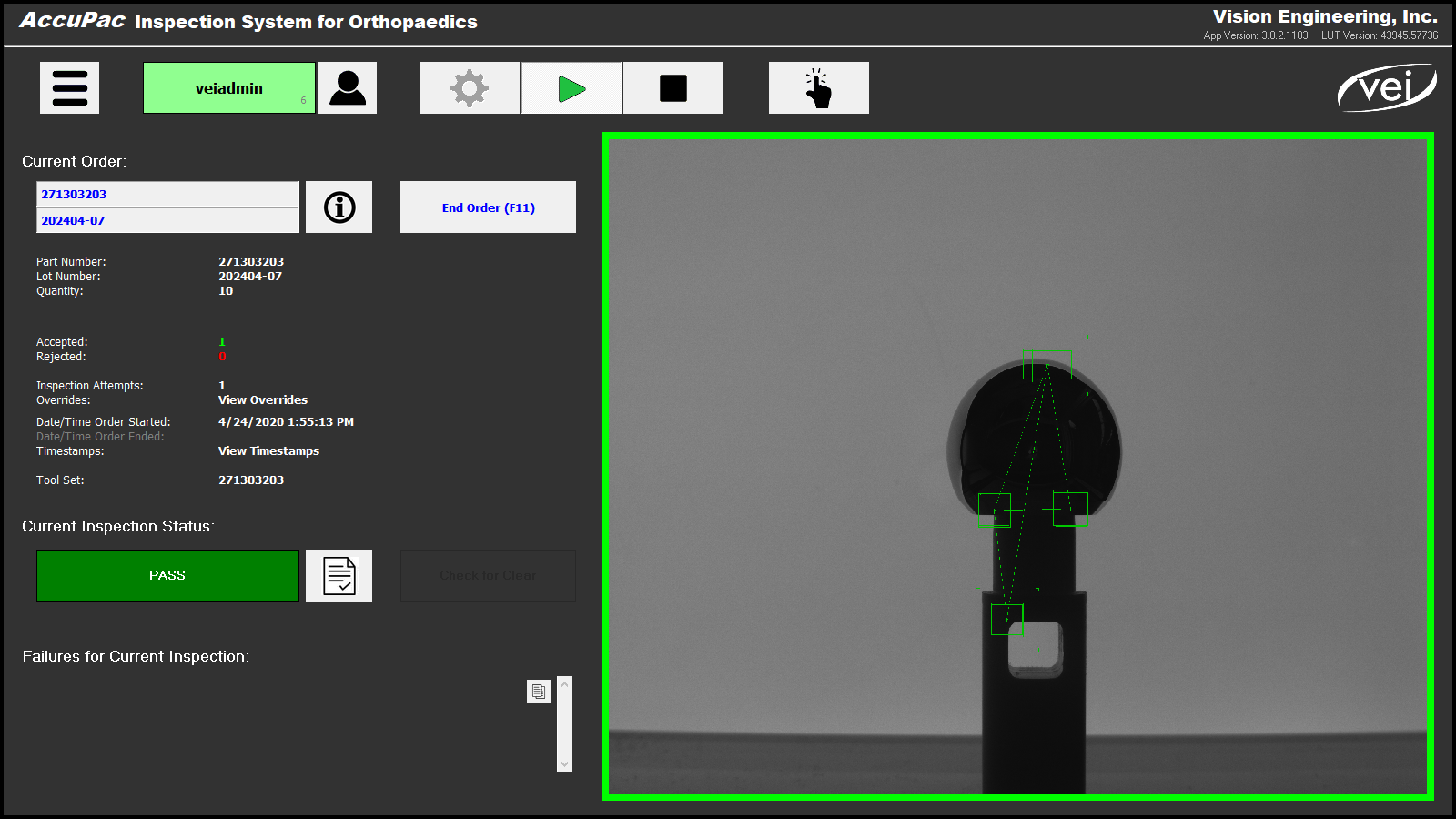

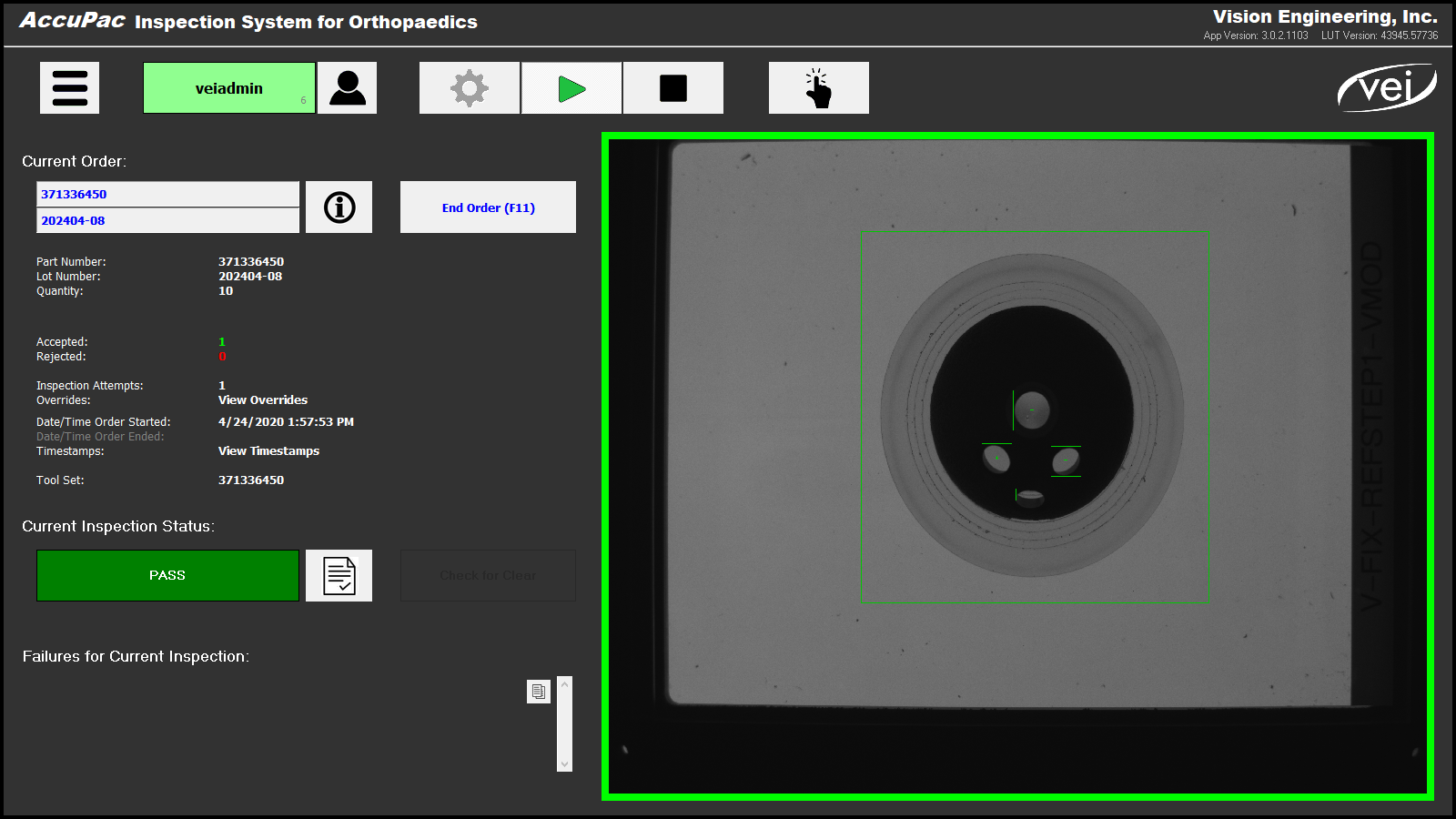

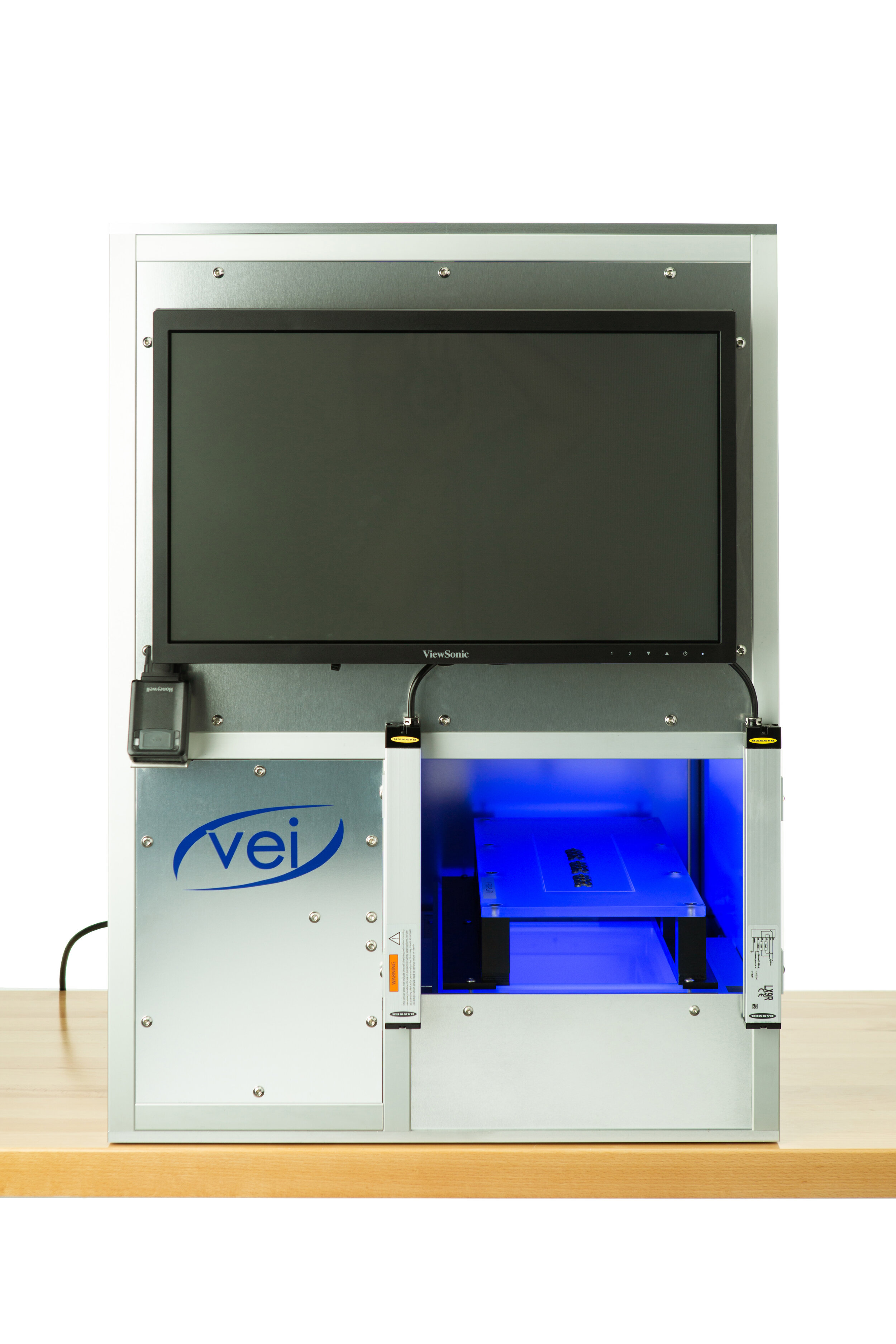

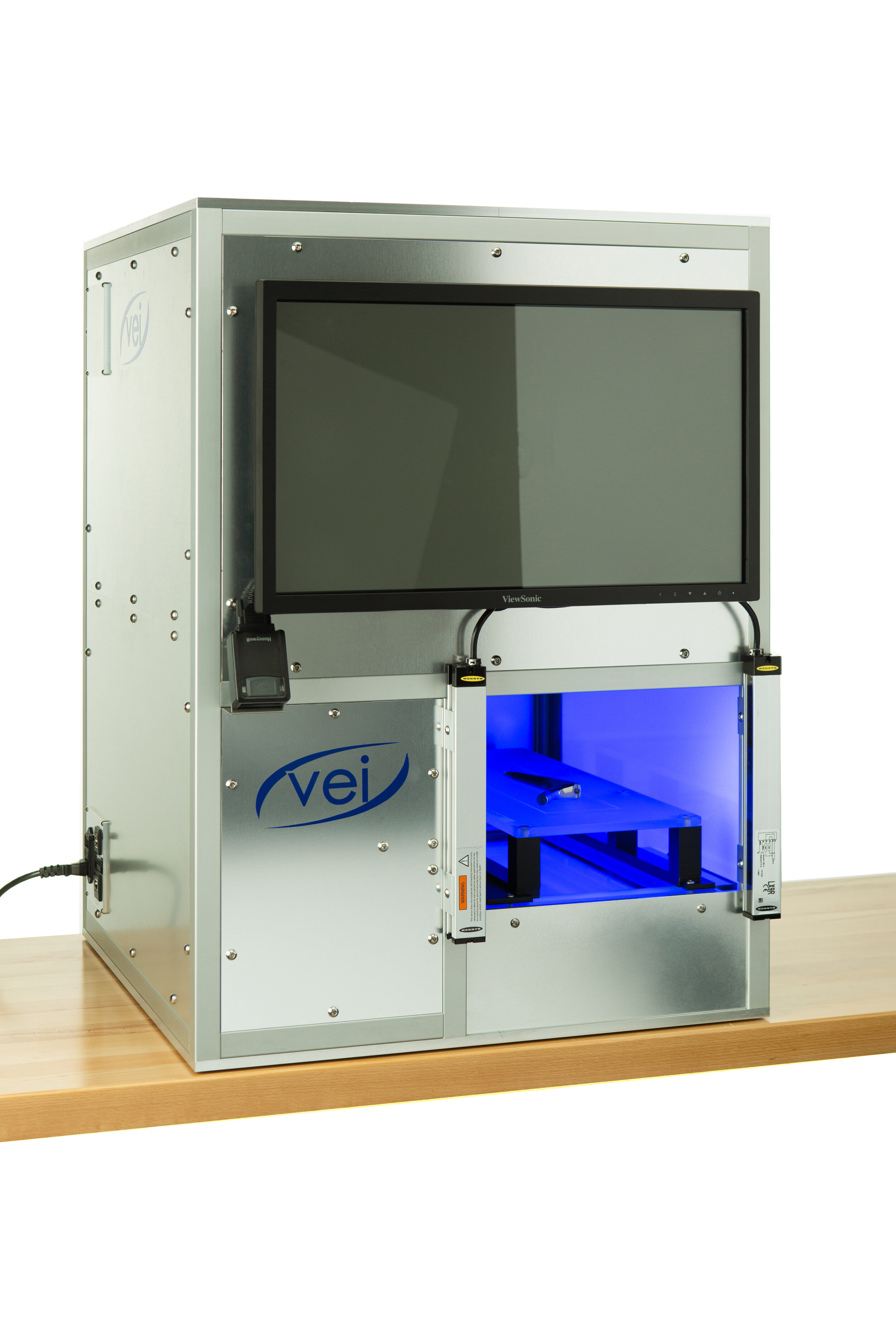

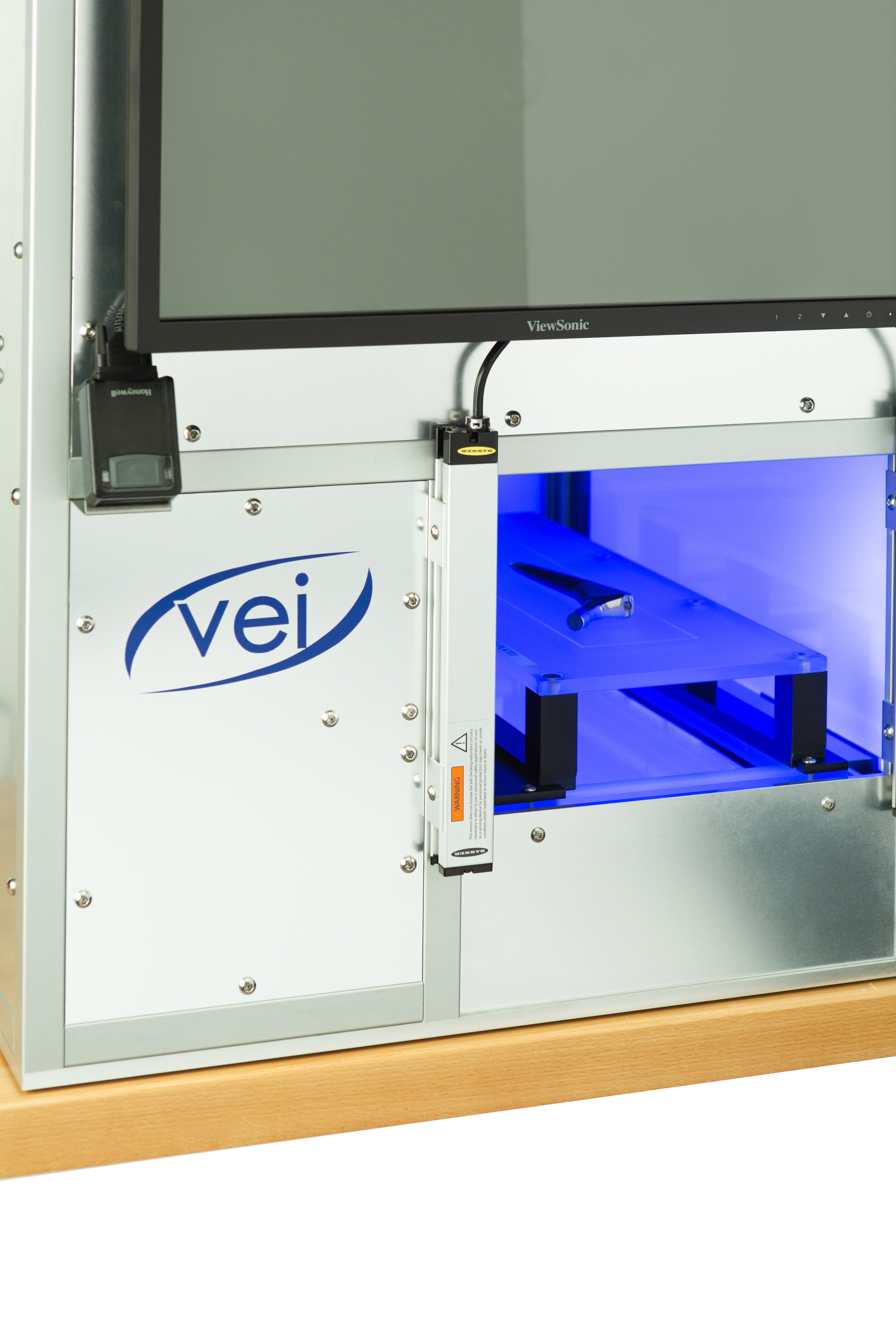

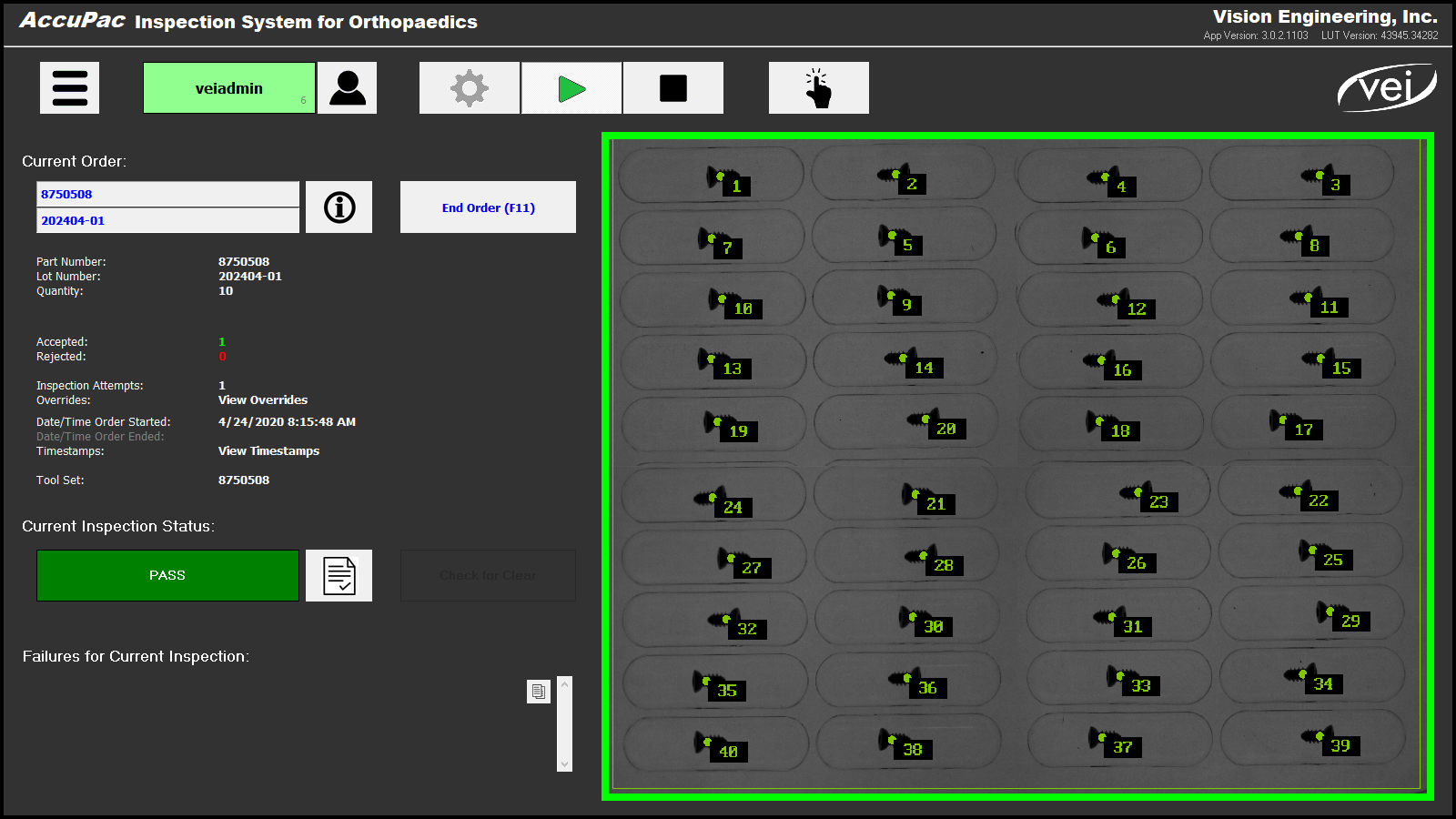

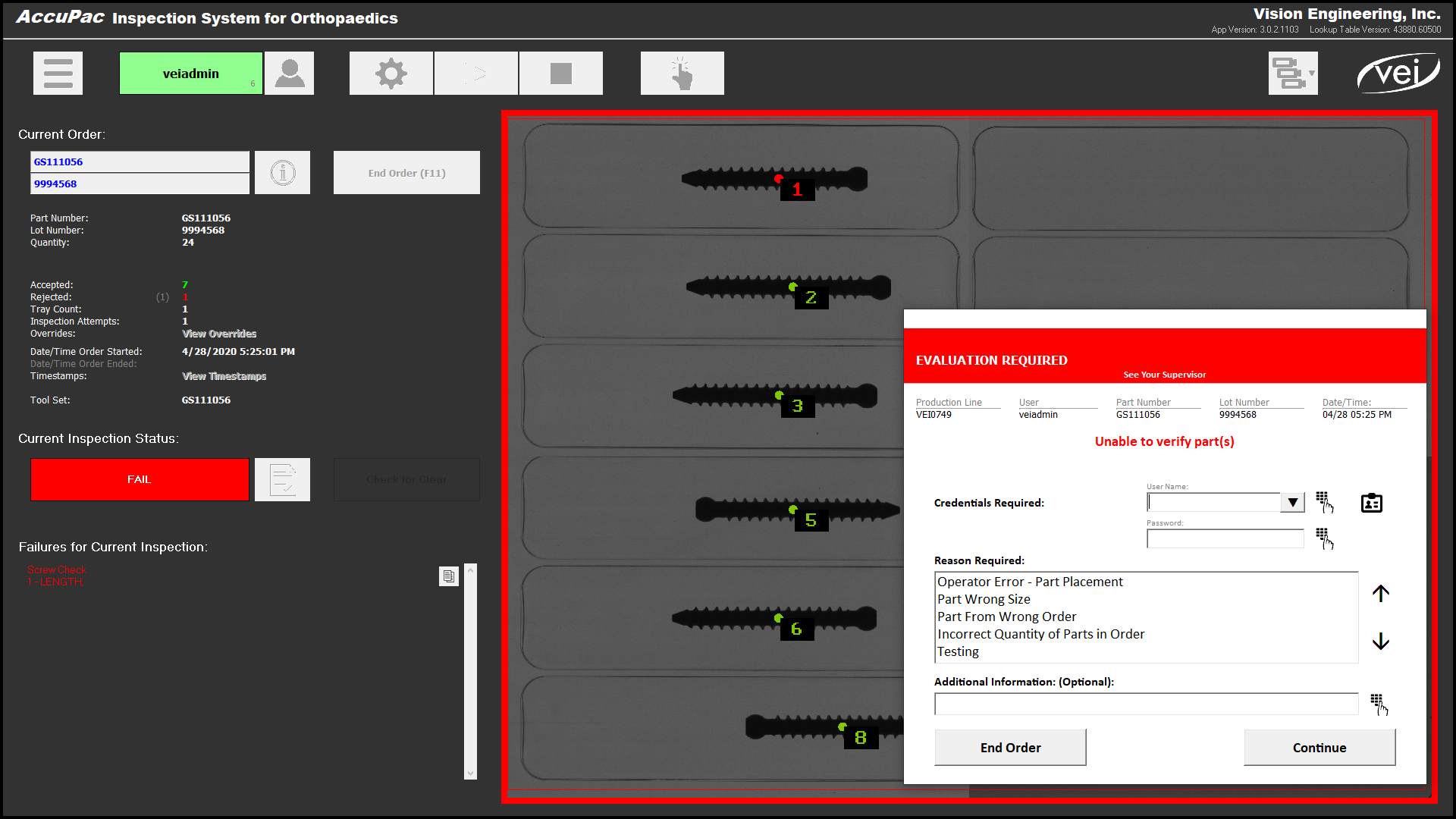

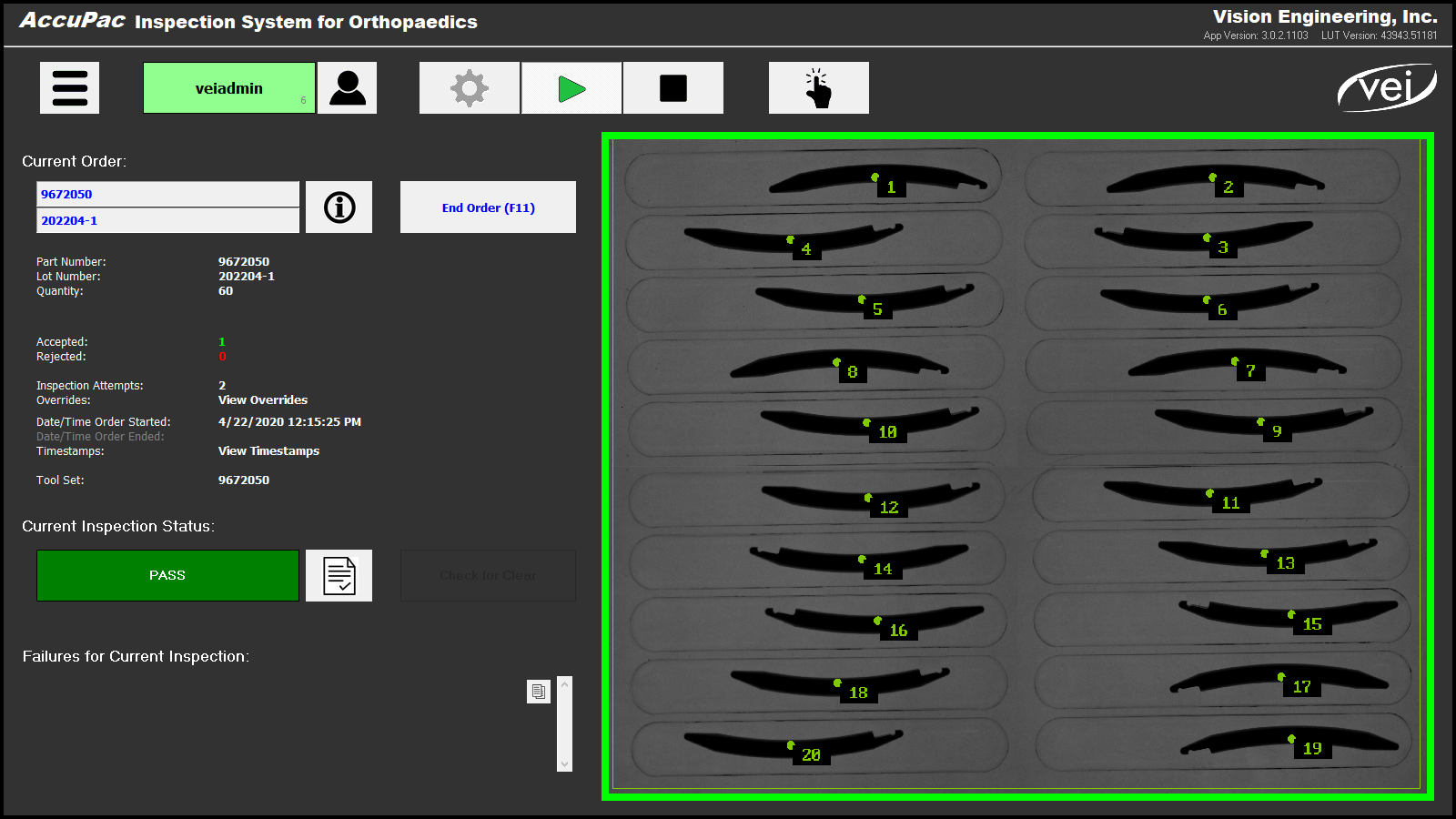

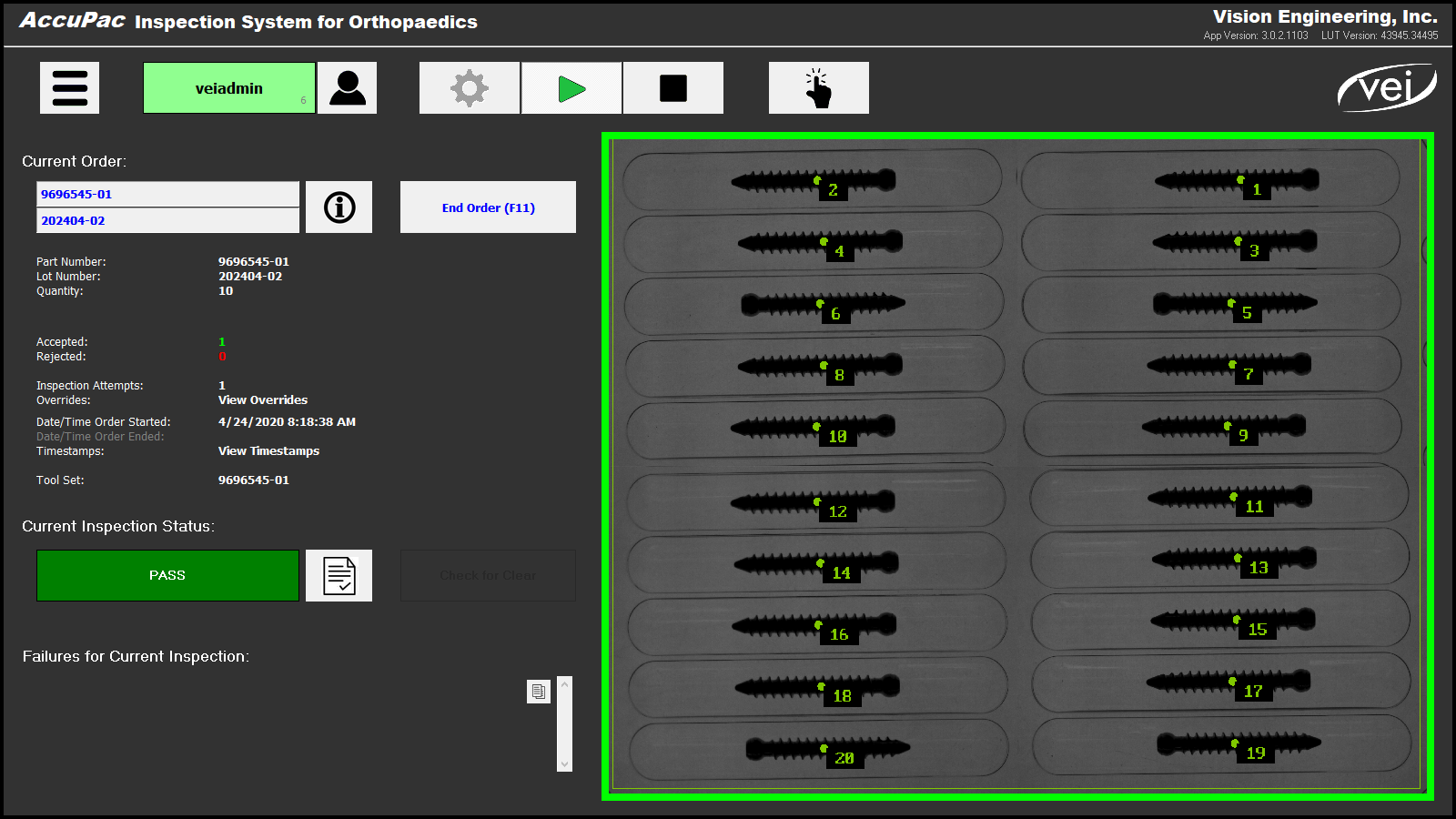

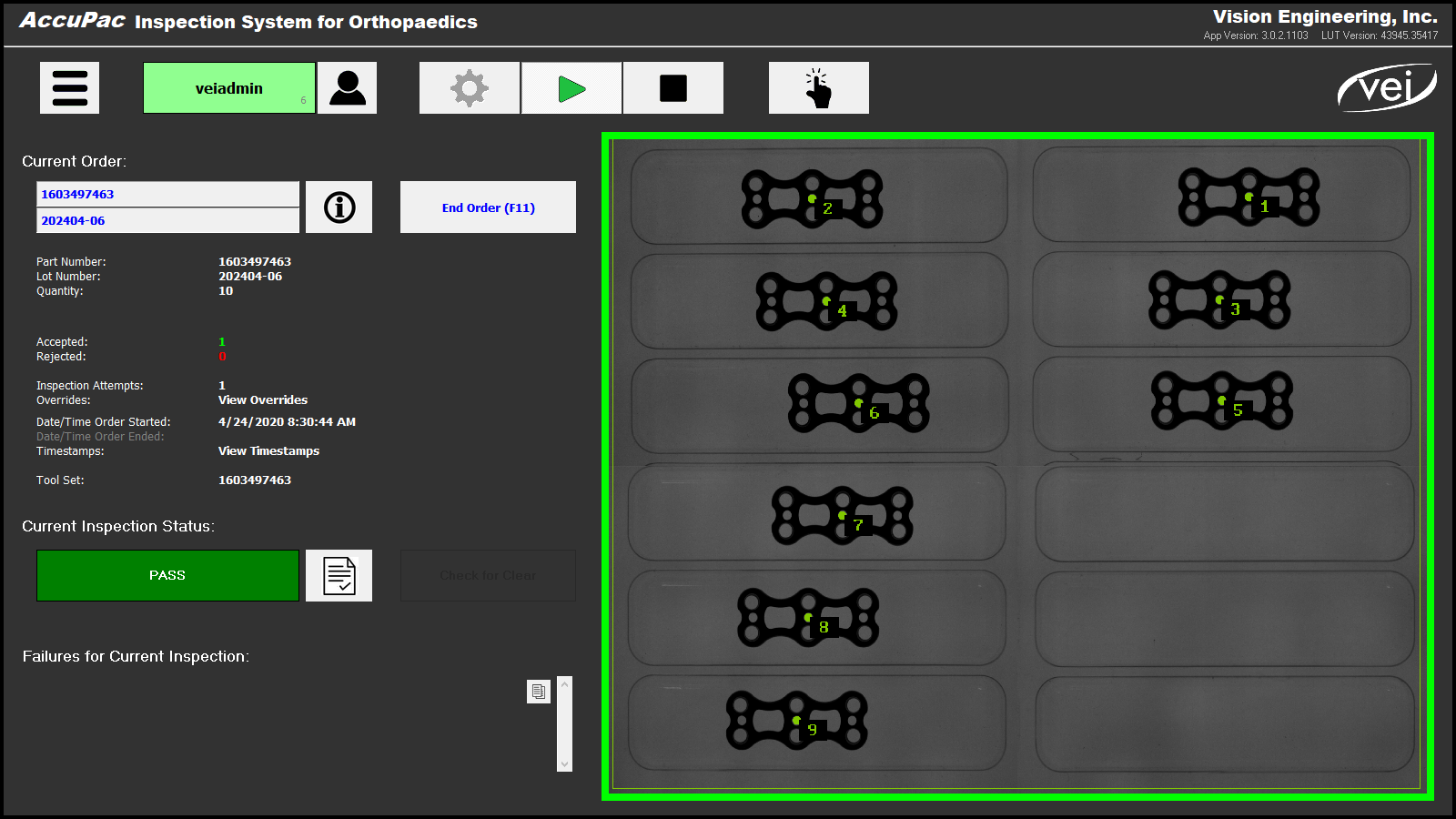

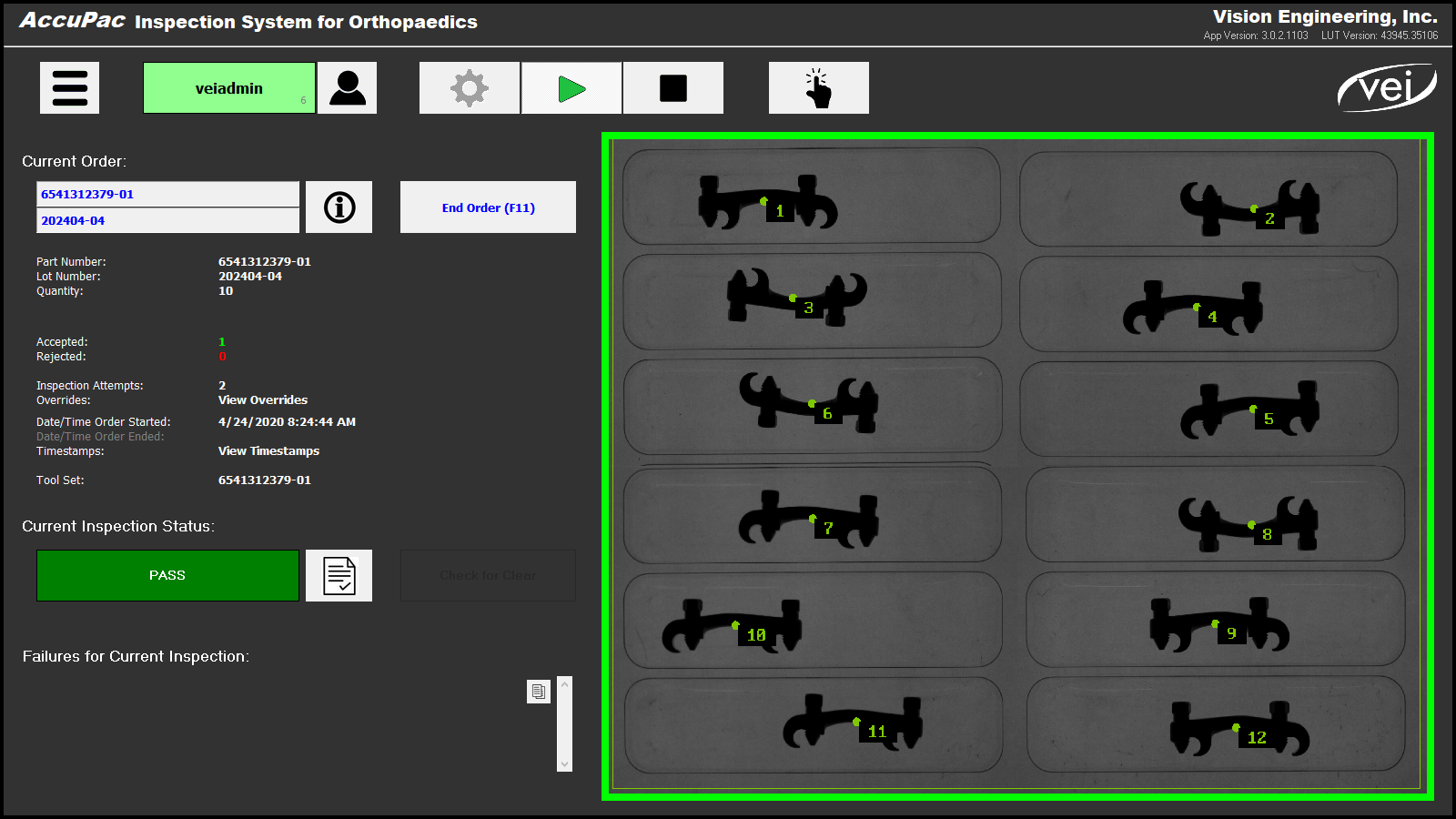

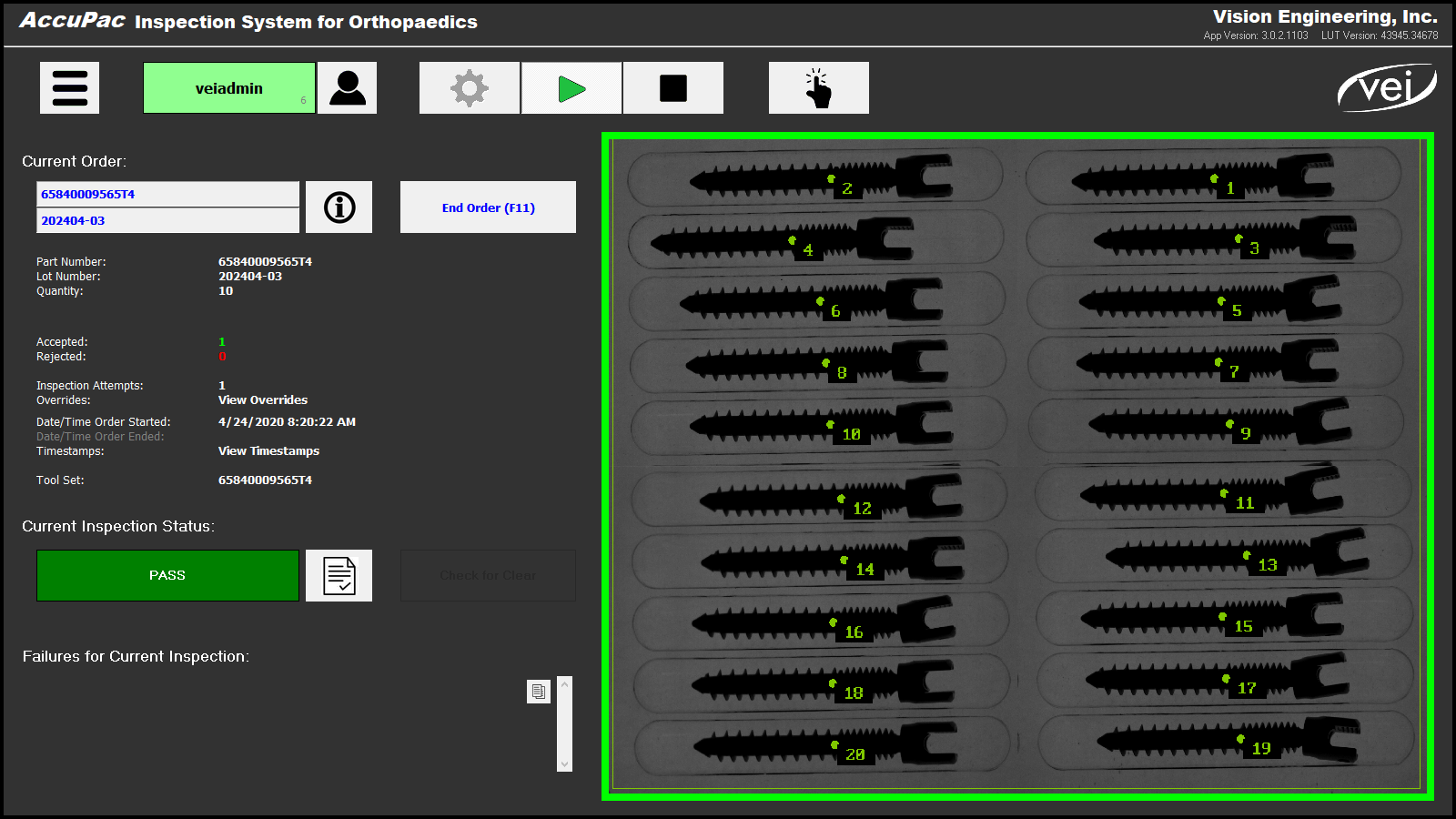

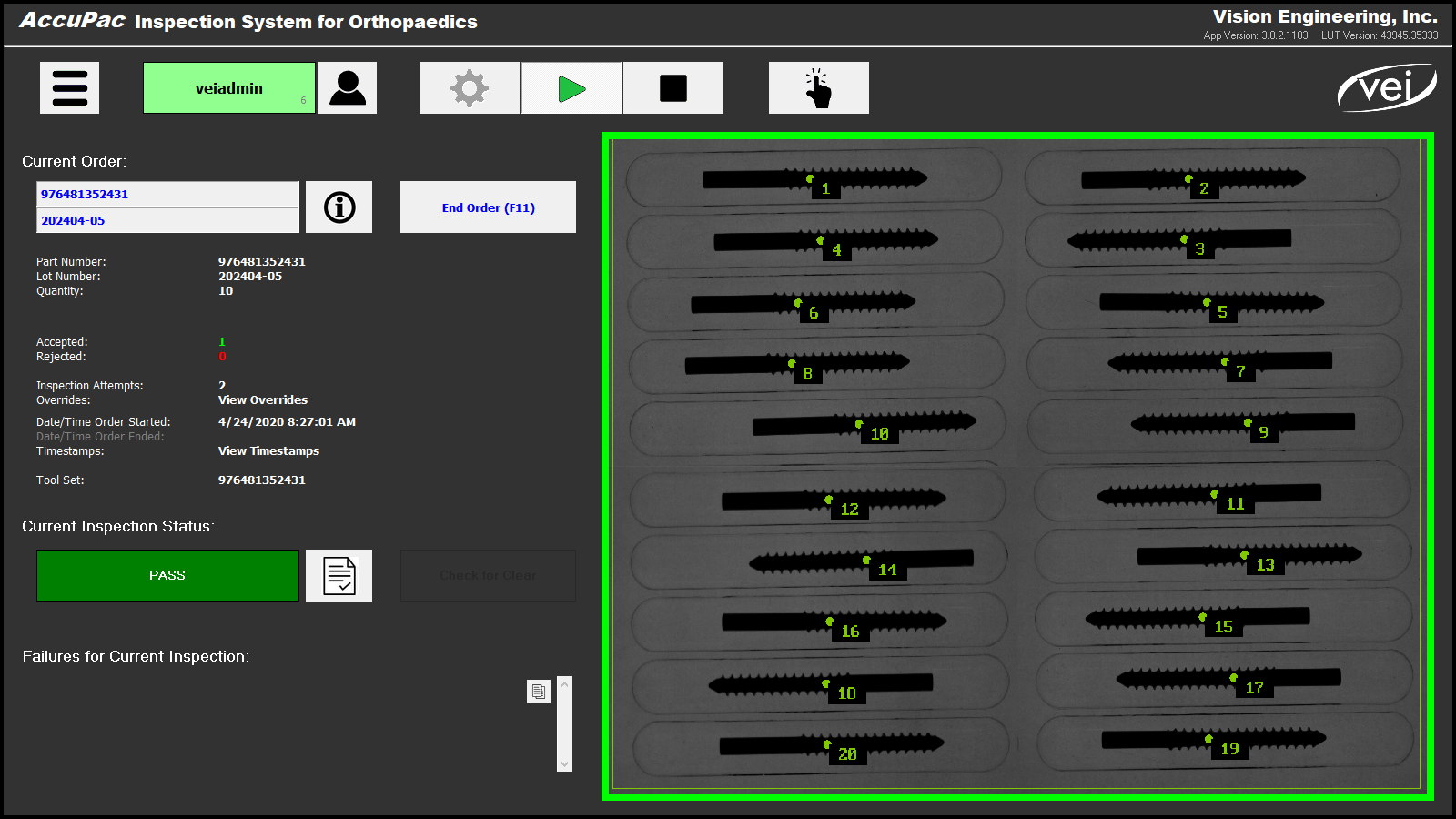

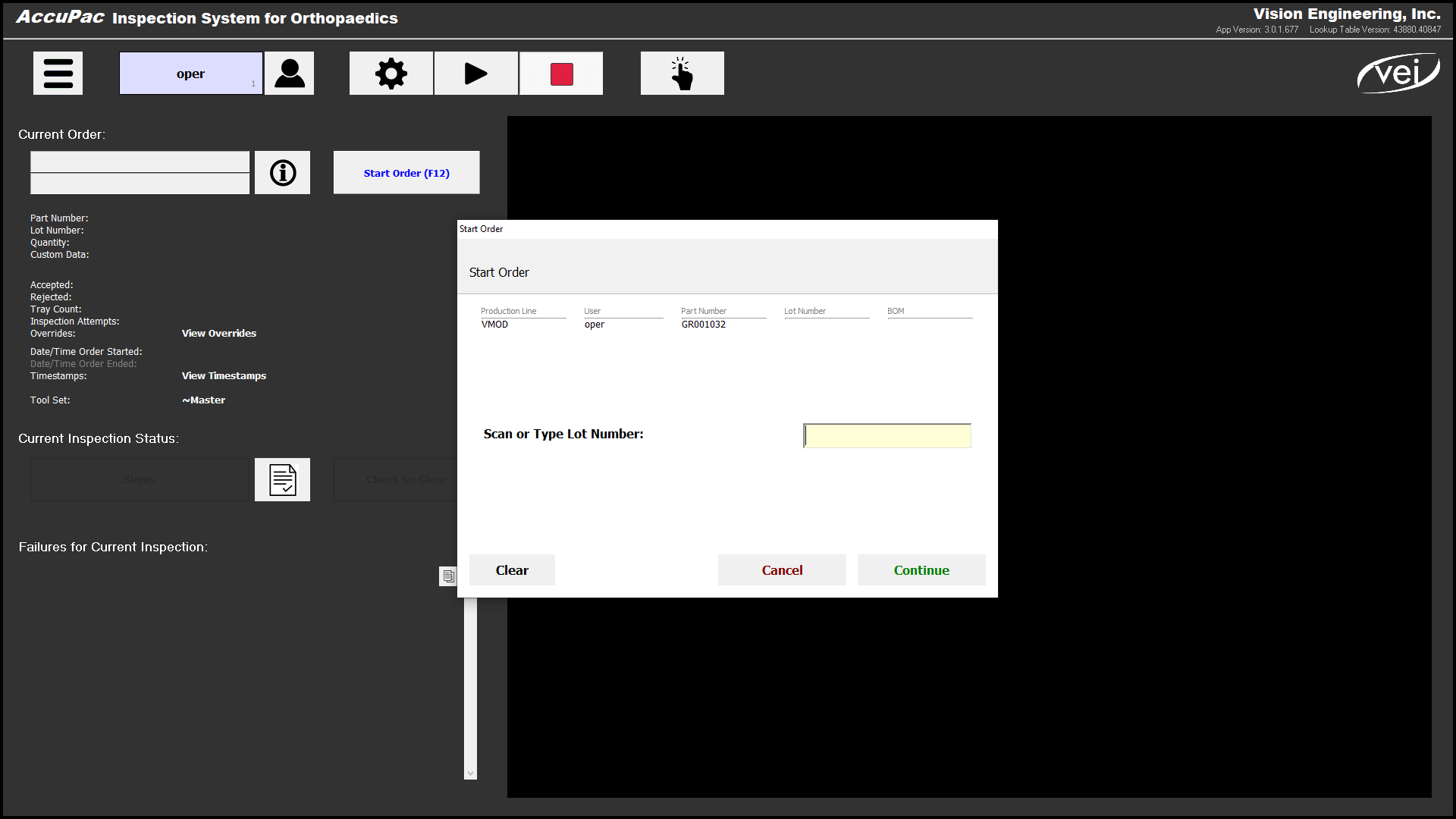

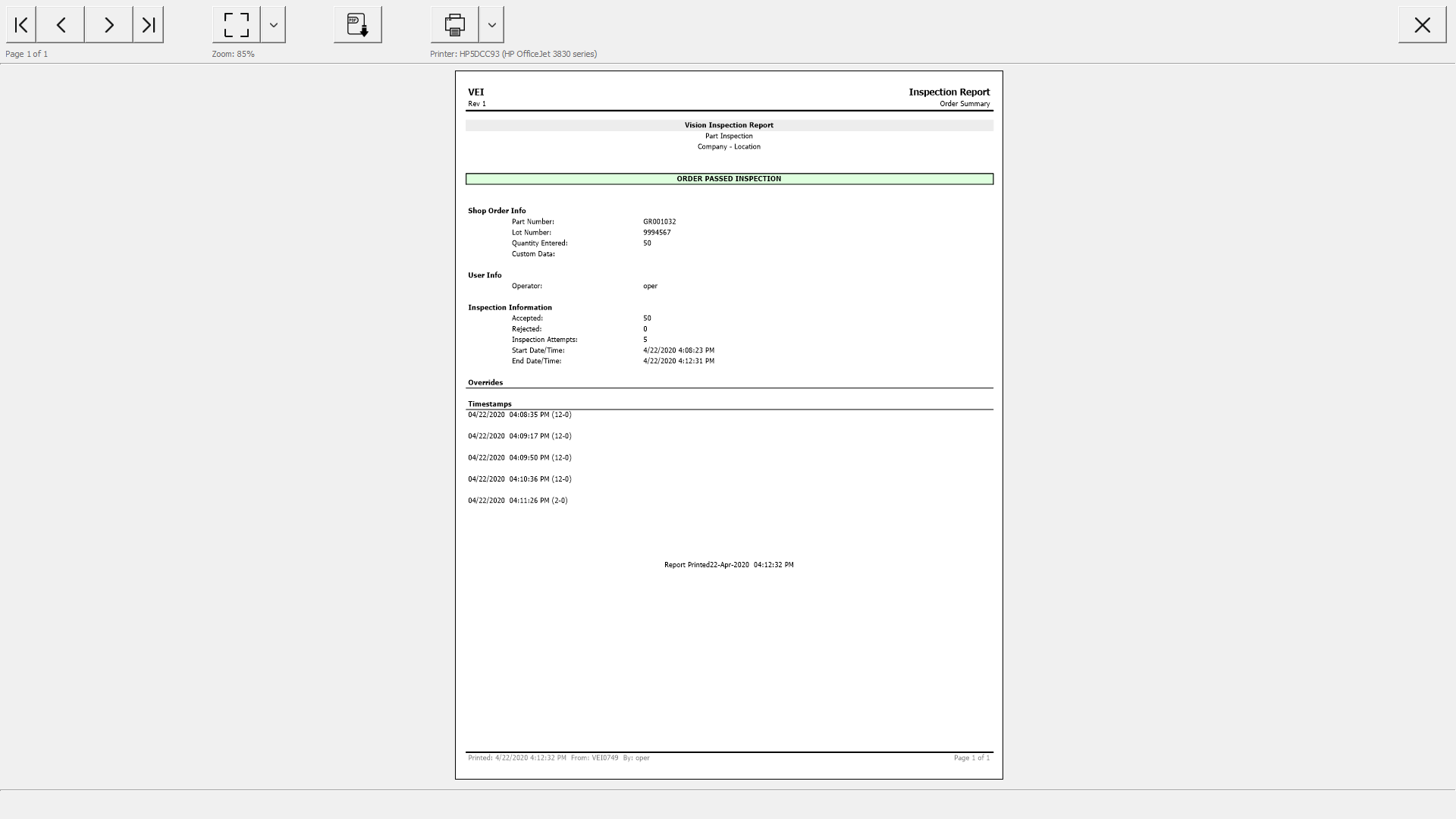

The VMOD-4000HRT system is an upgraded version of a solution that VEI has provided for more than a decade. The system is designed to rapidly perform part ID to ensure that large lots of screws/plates/implants are correct. The system can inspect parts in reusable or single use trays, as well as without the use of a tray. Utilizing the VMOD-4000HRT has been shown to drastically cut labor costs and liability in the sorting and verification of implantable devices. The system is capable of inspecting hundreds of parts in only seconds, with resolution to inspect very miniscule differences in parts such as microfacial screws, pins, set screws etc. The system is frequently deployed with a magnitude of part types and configurations with many customers having over 10,000 unique parts inspected by the system. The system has many optional configurations to aid the operator in ergonomics, such as automatic drawer , manual drawer , conveyor loading, robotic loading, and light curtains for automated inspection period the system can easily be integrated too existing plant infrastructure such as ERP systems, label generating software, QMS, MES applications, and many other digital and network based solutions. In addition to infrastructure integration, the system can be deployed with integration to other pieces of capital equipment such as sealers, laser etch, bagging systems.